hs dock

Use

58

Order h49 7144.907-333

NOTE

Damage to materials caused by contaminated /

unprocessed cooling lubricants!

For the product to function properly, in particular

for internal flushing with cooling lubricants and/or

when using tools with internal flushing, ensure

that the cooling lubricant is cleaned / processed,

and that it contains no particles measuring >100

microns [filtered with a mesh width of 100 mi-

crons].

NOTE

Damage to seals caused by using the wrong cool-

ant lubricants!

To clean the product, never use a cooling lubri-

cant that attacks and damages the sealing ele-

ments installed. Those installed sealing elements

can be made of NBR, Viton and PUR materials.

Never use cooling lubricants that contain ester or

a polar solvent.

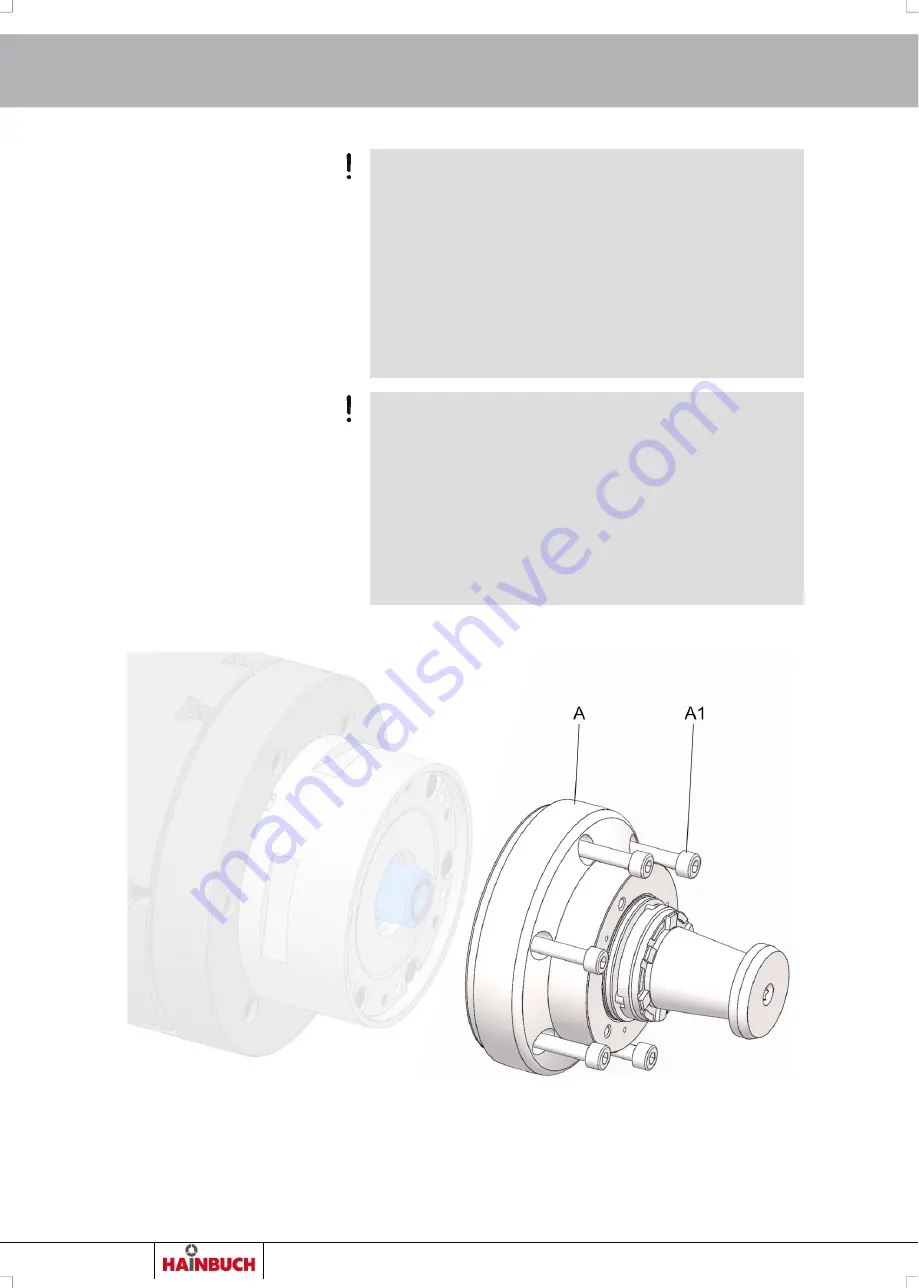

8.2 Installation of the clamping device

A

Clamping device

A1 Fixing screws clamping device

1. As described in the »Preparation of the machine for in-

stallation« chapter, prepare for the following steps.

2. Attach any lifting gear that may be required.