VII.

SERVICE AND MAINTENANCE

B. FLUIDS

115

FIG 115-1

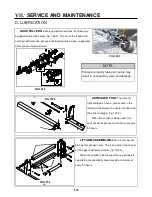

WHEEL HUB OIL

BONFIGLIOLI

OIL LEVEL

–

Each wheel hub should maintain a proper oil level at all

times. Less than that would limit lubrication and over full would cause over-

heating and damage. To check the oil level, position the hub so one of the

face plugs is positioned at 12 O’clock (fig. 115-1, item A). The other plug

will be either at 8 O’clock (fig. 115-1, item B). (When positioned correctly

the arrows in the center of the hub should make an “L”.) Remove the lower plug; if no oil comes out, the oil

level is too low. Check wheel hub oil level every 100 hours.

If SAE 80W/90 or SAE 85W/140 with EP features oil is needed, remove the top plug also and fill just until it

starts to come out the lower hole (approximately 40 ounces). With the oil at a satisfactory level, re-install plugs.

CHANGE

–

The wheel hub oil should be changed after the first 50 hours of field operation. Subsequently,

it should be changed every 500 hours or yearly (whichever comes first).

To change the wheel hub oil, position the plugs so that one is at the 6 O’clock position, and the other is

between the 2 and 3 O’clock positions. Remove the bottom plug to drain the oil. Once all of the oil is drained,

rotate the hub so that the plugs are in the filling position (fig. 115-1). Refill wheel hub with gear oil as described

above.

GENERAL MAINTENANCE-

If your sprayer is going to sit for an extended period of time, occasionally

rotate the hubs by driving the sprayer forward and backward at least 1/2 of a tire rotation to adequately coat all

internal hub parts. This will prevent rusting if moisture inadvertently entered the hub during an oil change. Fail-

ure to rotate the hub and disperse oil may cause rusting and internal damage to the hub.

A

B

FULL

LINE