6

Installation and Maintenance Manual, Compact CA

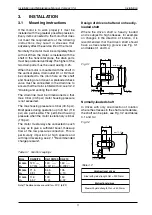

1.3 Functional description

1

3

4

5

6

7

D

8

A, C

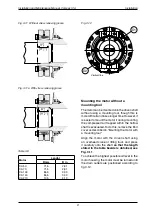

Fig. 1 The COMPACT CA motor

10

9

11

Hägglunds hydraulic industrial motor COM-

PACT CA is of the radial-piston type with a

rotating cylinder block/hollow shaft and a sta-

tionary housing. The cylinder block is mounted

in fixed roller bearings in the housing. An even

number of pistons are radially located in bores

inside the cylinder block, and the valve plate

directs the incoming and outgoing oil to and

from the working pistons. Each piston is wor-

king against a cam roller.

When the hydraulic pressure is acting on the

pistons, the cam rollers are pushed against the

slope on the cam ring that is rigidly connected

to the housing, thereby producing a torque.The

cam rollers transfer the reaction force to the

piston which are guided in the rotating cylinder

block. Rotation therefore occurs, and the torque

available is proportional to the pressure in the

system.

Oil main lines are connected to ports A and C

in the connection block and drain lines to ports

D1, D or D3

in the motor housing.

The motor is connected to the shaft of the

driven machine through the hollow shaft of

the cylinder block.The torque is transmitted by

using a mechanical shaft coupling, or alterna-

tively by splines.

The symmetrical design of the motor has made

it possible to design it as a two displacement

motor. This means that two different speeds

can be obtained for a given flow. The simplest

way of performing displacement change is by

connecting a special valve, direct to the flange

face on the connection block.

Valid patents

US 45110, US 00597995A, SE 456517,

EP 010915, JP 8316704, GB 1385693,

EP No 054437.

Quality

To assure our quality we maintain a Quality

Assurance system, certified to standard ISO

9001, EN 9001 and BS 5750; Part 1.

General

1. Cam ring

. Cam roller

3. Piston

4. Shaft coupling

5. Cylinder block /

hollow shaft

6. Cylinder block / spline

7. Front end cover

8. Cylindrical roller

bearing

9. Connection block

10. Valve plate

11. Axial bearing

A = inlet or outlet port »A«

C = inlet or outlet port »C«

D = drain port

F4 = Flushing

F4