3

Installation and Maintenance Manual, Compact CA

Installation

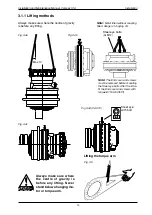

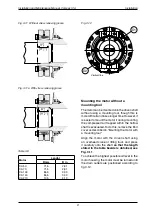

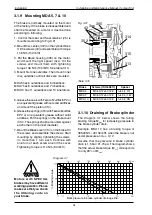

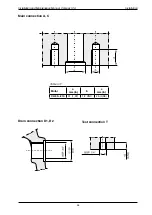

3.1.4b Mounting the motor onto the driven shaft - splines

A3

_

ANNICA

Oil to be filled before

tightening G1 plugg

Mounting kit

478 369-801

For flange mounted motors, the spline shall nor-

mally not be subject to radial load.With no radial

load, the splineshaft can be oiled before mounting

the motor. If the motor is subject to radial load, the

splines shall be filled up with oil.

- Lubricate and install o-ring at leading edge of

motor bore.

- Check shaft/splines for burrs and lubricate shaft/

splines.

- Mark spline tooth location on outside of motor bore

to assist alignment during installation.

- Mount the motor on to the shaft.

- Bolt the motor to the flange.

- Fill up hydraulic oil to the G1 plug.

- Torque the G1 plug. M

V

=15 Nm/90 lbf

.

ft.

- Mount the cover. M

V

=81 Nm/59 lbf

.

ft.

Oil to be filled before

tightening bolt M0

L=100 mm

Mounting kit

478 369-801

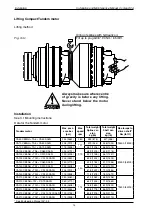

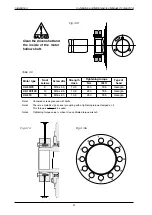

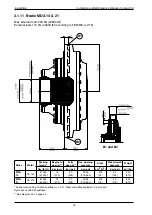

Torquearm mounted motors

Motors that carry radial load, must have the splines

oiled. The motor can be used for horizontal mount-

ing and mounting with motor shaft pointing down-

wards.

- Mount torque arm to motor with bolts supplied.

Align with oil connection ports as required.

- Lubricate and install o-ring at leading edge of

motor bore.

- Check shaft/splines for burrs and lubricate shaft/

splines.

- Mark spline tooth location on outside of motor bore

to assist alignment during installation.

- Mount the motor on to the shaft.

- Fill up hydraulic oil to the G1 plug.

- Mount special designed bolt.

- Torque the bolt. M

V

=385 Nm/80 lbf

.

ft.

- Mount the cover. M

V

=81 Nm/59 lbt

.

ft.

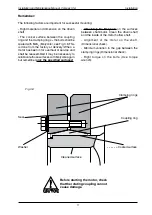

Flange mounted motors

o-ring

If oil here, it can be used

for the spline. Then take away

the o-ring.

o-ring

10 (0,4) during

filling of oil