3

Installation and Maintenance Manual, Compact CA

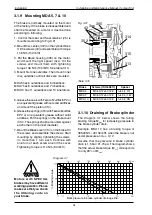

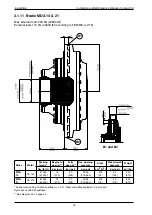

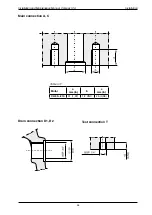

Disassembly and assembly of MDA 14 & 21

Installation

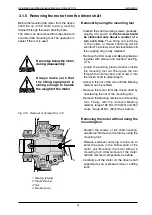

1. Start the disassembly by slightly

loosening the screws (40). Not more

than 1 turn each. Continue with 1 turn

of each screw around the cover until

the pre-load of the Belleville springs

(315)(Cup springs) is zero. After that the

screws can be removed and the Brake

cover (314) lifted off.

. The Brake piston (313) can be removed

by installing 3 screws (M8) and be lifted

off by using the screws.

3. Inner and outer discs (318, 30) can be

removed and the spacer (308) in place

can be removed.

4. Loosen the screws (43), and take off the

seal retainer (5).

5. Control the seal and mount seal retainer

(5) as figure. Oil the screws (43) and

assembly with torque 114 Nm (84

lbf·ft).

6. Mount spacer for MDA 14 (308). Mount

first one outerdisc, then innerdisc,

outerdisc until all discs are mounted.

N.B Matched disc set.

MDA 14 has 8 outerdiscs and 7 innerdiscs

MDA 1 has 11 outerdiscs and 10

innerdiscs

7. Grease the seals with Texaco Multifak

EP or an equivalent grease without

solid additives and mount the piston

(313).

Please read this in-

struction carefully

before starting the

disassembly!

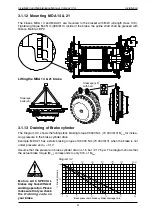

8. Grease the springs (315) with Texaco Multifak

EP or an equivalent grease without solid

additives, put the springs on the Brake cover

(314). The springs shall be mounted against

each other in the innerdiameter.

9. Mount the Brake cover (314) on the brake, oil the

screws and assembly the screws. Start mounting

by slightly tightening the screws, no more than

one turn each. Continue with one turn of each

screw around the cover, tightening torque is 114

Nm (84 lbf·ft).

5

43

30

318

40

315

314

313

308

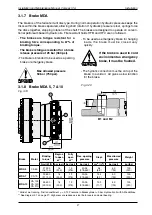

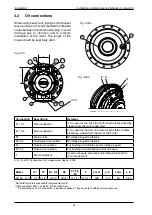

3.1.14 Control of braking torque

The motor can be used for controlling the torque for the brake.

Start to drain the brake to tank, and increase pressure for the motor until it starts to rotate. Pressure

drop over the motor x T

s

for the motor gives braking torque for the brake.

If the motor can not rotate the brake, increase back pressure in the brake cylinder until the motor

can rotate the brake.

Braking torque = Pressure drop over the motor x motor torque T

s

x 100/ % Braking torque in diagram

3.1 or 3.. With full torque and 10 rpm, the brake must not rotate more than max 10 sec.