11

Installation and Maintenance Manual, Compact CA

3.

INSTALLATION

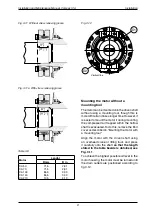

Fig. 3.1

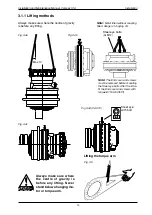

Normally-loaded shaft

In drives with only one direction of rotation

where the stresses in the shaft are moderate,

the shaft can be plain, see Fig. 3. and tables

3.1 and 3.4

Fig. 3.2

Note! The dimensions are valid for +0°C (68°F)

0

-0,05

0

-0,00098

0

-0,05

0

-0,00098

0

-0,05

0

-0,00098

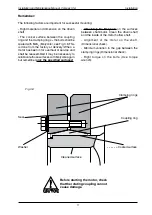

E

C

A

D

30°

R 3,2

G

F

6±0,5

B±0,5

(B±0,02)

(0,24±0,02)

R 50

(R 1,97)

a

3.1

Mounting instructions

Design of driven shaft end on heavily-

loaded shaft

Where the driven shaft is heavily loaded

and is subject to high stresses, for example

on changes in the direction of rotation, it is

recommended that the driven shaft should

have a stress relieving groove; see Fig. 3.1

and tables 3.1 and 3.4.

If the motor is to work properly it must be

installed with the greatest possible precision.

Every item connected to the motor that does

not meet the requirements of the following

instructions may result in stresses that

adversely affect the service life of the motor.

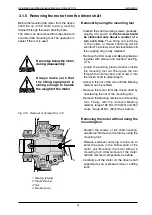

Normally the motor must be completely filled

with oil. When the motor is installed with the

shaft in the horizontal plane, the drain ports

must be positioned vertically. The higher of the

two drain ports must be used: see fig. 3.5.

When the motor is mounted with the shaft in

the vertical plane, drain outlet D1 or D must

be connected to the drain hole on the shaft

end housing or end cover. A preloaded check

valve must be connected in the drain line to

ensure that the motor is filled with oil; see 3..

"Draining and venting the motor".

The drain line must be dimensioned so that

max. 3 bar (43.5 psi) motor housing pressure

is not exceeded.

The max housing pressure is 3 bar (43.5 psi).

Brief peaks during operation up to 8 bar (116

psi) are permissible. The permitted housing

pressure when the motor is stationary is 8 bar

(116 psi).

The motor must always be connected in such

a way as to give a sufficient boost, make-up

flow at the low pressure connection. This is

particularly important at high speeds and

with rapid reversing, see .1 "Recommended

charge pressure".

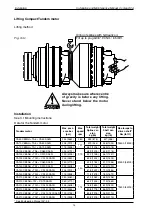

Installation

Table 3.2

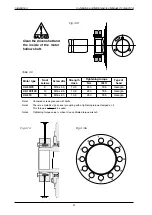

Table 3.1 Valid for couplings

Max

Max

Unidirectional drives

Bidirectional drives

Steel with yield strength

= 300 N/mm

Rel

Steel with yield strength

= 450 N/mm

Rel

Dim

CA50/70

CA100/140 CA210

A mm

in

10

4,744

140

5,5118

160

6,99

B mm

in

71,5

,81

84,5

3,33

105

4,13

C mm

in

116

4,57

133

5,4

153

6,0