Model G0833P (Mfd. Since 06/17)

-69-

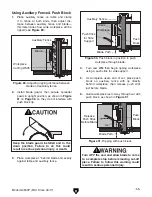

Adjusting Bent Spreader/Riving Knife

1. DISCONNECT MACHINE FROM POWER!

2. Bend spreader or riving knife by hand while

installed, then follow

Steps 1–3 in Checking

Alignment on Page 67 to determine if it is par-

allel with blade and inside "Alignment Zone"

(refer to

Figure 115 Checking Alignment on

Page 67).

— If this doesn't work, remove it to straighten.

— If you cannot straighten it properly,

replace it.

4. Re-install table insert.

5. Follow Checking Alignment, Steps 1–3.

— If spreader/riving knife is in alignment

zone, no additional steps are necessary.

—If spreader/riving knife is still not in align-

ment zone, continue adjusting set screws

on mounting block as necessary to cor-

rectly position spreader/riving knife.

6. Tighten (2) cap screws on mounting block to

secure spreader/riving knife adjustment.

Fence Adjustments

There are four main adjustments for the fence:

height off the table, squareness, parallelism with

the miter slot, and clamping pressure. These

adjustments are interconnected and some repeti-

tion may be needed when adjusting.

Tools Needed

Qty

Hex Wrench 6mm .............................................. 1

Square ............................................................... 1

Felt-Tipped Marker ............................................ 1

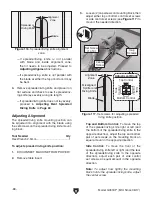

Figure 118. Location of screws used to adjust

fence parallelism and clamping pressure.

Rear Set Screws

Front Lock Nuts

and Adjustment Screws

Height and Square

The fence should be adjusted high enough off the

table so that it does not drag across the surface or

allow wood chips to get caught between the fence

and table. Also, the fence face must be square to

the table in order to produce accurate cuts.

To check/adjust fence height and squareness

to table:

1. DISCONNECT MACHINE FROM POWER!

2. Remove fence from saw and place it on a flat

surface.

3. Unscrew front lock nuts and adjustment

screws shown in

Figure 118 until they are

barely threaded into fence flange.

4. Back out rear set screws until they are just

threaded into fence flange (see

Figure 118).

Summary of Contents for Polar Bear G0833P

Page 92: ......