-66-

Model G0817 (Mfd. Since 05/16)

Aligning Wheels

The following adjustment was performed at the

factory and should not need to be performed

again unless there is a wheel alignment problem,

or one or more wheels are replaced.

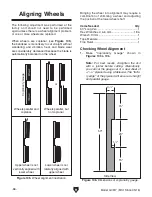

When wheels are coplanar (see

Figure 105),

the bandsaw is more likely to cut straight without

wandering; and vibration, heat, and blade wear

are considerably decreased because the blade is

automatically balanced on the wheel.

Checking Wheel Alignment

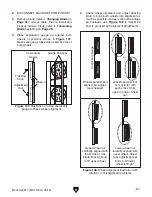

1. Make "Coplanarity Gauge" shown in

Figures 105 & 106.

Note: For best results, straighten the 2x4

with a jointer before cutting. Alternatively,

you can cut the gauge out of a new sheet of

1

⁄

2

"–

3

⁄

4

" plywood using a tablesaw. The "facto-

ry edge" of the plywood will ensure a straight

and parallel gauge.

Figure 106. Dimensions of coplanarity gauge.

Side View

53"

3-

1

⁄

2

"

15"

15"

23"

1-

1

⁄

2

"

Bringing the wheel into alignment may require a

combination of shimming a wheel and adjusting

the position of the lower wheel shaft.

Items Needed

Qty

53" Long 2x4 ..................................................... 1

Hex Wrenches 4 & 6 mm .............................1 Ea

Wrench 13mm ................................................... 1

Tape Measure .................................................... 1

Fine Ruler .......................................................... 1

Figure 105. Wheel alignment illustration.

or

Wheels parallel and

coplanar.

Wheels parallel, but

not coplanar.

Upper wheel is not

vertically aligned with

lower wheel.

Lower wheel is not

laterally aligned with

upper wheel.

Coplanarity Gauge

Summary of Contents for G0817

Page 88: ......