-62-

Model G0817 (Mfd. Since 05/16)

Adjusting Wheel

Brushes

The lower wheel has brushes (see

Figure 97) that

are designed to sweep sawdust off the tire and

blade during operation. In order to work properly,

the brushes must make firm contact with the tire.

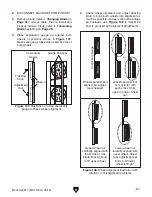

Adjusting Quick-

Release Lever

The blade tension quick-release lever was adjust-

ed at the factory for use with the pre-installed

blade. However, because actual blade lengths

may vary slightly by manufacturer, whenever you

install a new blade, you may need to adjust the

quick-release adjustment screw so that the blade

tension quick-release lever works correctly.

Tools Needed:

Qty

Hex Wrench 5mm .............................................. 1

Wrench 10mm ................................................... 1

To adjust blade tension quick-release lever:

1. Tension blade (refer to Tensioning Blade,

beginning on

Page 28 for more information).

2. DISCONNECT MACHINE FROM POWER!

3. Rotate blade tension quick-release lever

clockwise to up position to release blade

tension.

4. Loosen jam nut on tension adjustment screw,

then loosen screw 7-10 turns (see

Figure 98).

Figure 98. Location of tension adjustment screw,

jam nut, and wheel block plate.

Tension

Adjustment

Screw

Jam Nut

Wheel

Block Plate

Tools Needed:

Qty

Wrench/Socket 10mm ....................................... 2

To adjust wheel brushes:

1. DISCONNECT MACHINE FROM POWER!

2. Open lower wheel cover.

3. Loosen hex bolts and lock nuts that secure

wheel brushes in place (see

Figure 97).

4. Adjust wheel brushes so they make firm,

even contact with the wheel without bending

the bristles, then retighten hex bolts and cap

screws to secure wheel brushes in place.

Figure 97. Location of wheel brushes.

Wheel

Brush

Hex Bolts

Lock

Nut

Lock

Nut

Wheel

Brush

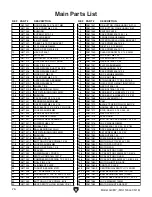

Summary of Contents for G0817

Page 88: ......