Model G0817 (Mfd. Since 05/16)

-63-

5. Rotate blade tension quick-release lever

counterclockwise to down position to apply

tension to blade.

6. Tighten tension adjustment screw (see

Figure 98) until it contacts wheel block plate,

then back it off 1-2 turns.

7. Retighten jam nut.

Adjusting Guide

Post Parallelism

The guide post assembly should remain parallel

with the blade front to back and side to side along

its length of travel. If it does not, follow these

instructions to adjust it.

Important: Make sure the table is aligned with the

blade from side to side and front to back before

beginning these procedures (refer to

Aligning

Table on Page 36 for detailed instructions).

Tools Needed:

Machinist's Square ............................................ 1

Small Ruler ........................................................ 1

Hex Wrench 4mm .............................................. 1

Hex Wrench 5mm .............................................. 1

Hex Wrench 8mm .............................................. 1

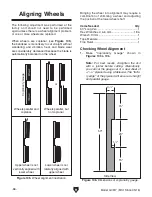

Checking/Adjusting Guide Post

Parallel with Blade Side to Side

1. DISCONNECT MACHINE FROM POWER!

2. Loosen guide post lock knob, lower guide

post to within 1" of table top, then tighten

knob.

Guide Post

(Front View)

Figure 99. Example of checking guide post

squareness.

3. Place machinist's square on table next to

right-hand side of guide post, as shown in

Figure 99.

— If there is no gap between square and

guide post along its full length, no adjust-

ments need to be made. Proceed to next

procedure.

— If there is a gap between square and the

guide post, guide post is not parallel to

blade. Go to

Step 4.

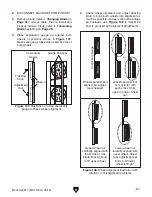

4. Loosen each of the four cap screws shown in

Figure 100

1

⁄

4

-turn

.

Figure 100. Guide post adjustment screws.

5. Gently tap lower part of guide post in appro-

priate direction until there is no gap between

square and guide post.

6. Tighten cap screws shown in Figure 100.

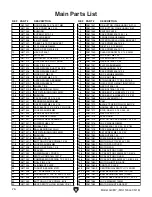

Summary of Contents for G0817

Page 88: ......