100

Test Operation, Troubleshooting and Maintenance

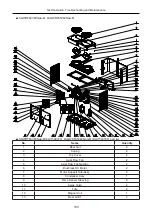

(2) Recharge refrigerant

Low-pressure gauge

High-pressure gauge

Manifold gauge

Hose

Hose

Refrigerant tank

Charging process

Excessive or deficient refrigerant may cause abnormal operation, malfunction or damage to a

compressor, so charge volume must comply with the requirements on the unit nameplate which have been

decided in strict tests; The figure may serve as a reference; a charge process is as follows (one system

as an example):

Step 1: Place a refrigerant container on an electronic scale and connect the container and the pressure

gauges by a flexible tube.

Step 2: Remove gases inside the flexible tube—half turning the shut-off valve of the container, loosen

the joint device between the flexible tube and pressure gauge; tighten the joint device when a sound is

sent out for 5s.

Step 3: Power up and down the electronic scale to enable it to reset.

Step 4: Ensure that the flexible tube has been evacuated and the scale reset, turn on all valves

connecting refrigerant containers and the unit; charge refrigerant required by the nameplate to prevent

oil dilution caused by excessive charging, and inhibit a capacity decline of the unit induced by insufficient

charging; when the unit is running, make sure it is gaseous refrigerant (as possible as it can be) from a

refrigerant container (that cannot be turned upside down) that is injected into refrigerant nozzles on intake

lines; when the unit powered down, be sure to charge refrigerant via the refrigerant nozzle at the high-

pressure side (if there is no nozzle at the high-pressure side, low-pressure side is an alternative.) in case

of liquid slug.

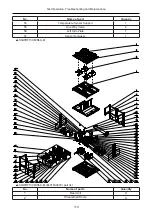

4.5.2 Air removal

When there is air trapped in the system, expel them before charging refrigerant. The whole system

must be vacuumed in accordance with the steps stated below.

(1)

Connect pipes for vacuuming at both the low and high pressure sides.

(2) Start the vacuum pump for vacuuming.

(3) When it reaches the targeted vacuum degree, charge refrigerant into the system. See the

nameplate for type and charging mount of refrigerant. Do charging from the low pressure side. A

manifold gauge should be connected to both the low and high pressure sides.

(4)

Refrigerant charging would be affected by environment temperature. If refrigerant is undercharged,

start the water pump to circulate chilled water and meanwhile start the unit for refrigerant adding. In

this case, vapor refrigerant should be charged.

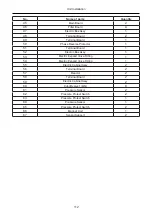

Summary of Contents for LSQWRF35VM/NaA-M

Page 5: ...1 Product Product...

Page 18: ...14 Unit Control Unit Control...

Page 29: ...25 Unit Installation Unit Installation...

Page 58: ...54 Unit Installation 3 5 7 Electric wiring digram 1 LSQWRF35VM NaA M...

Page 59: ...55 Unit Installation 2 LSQWRF60VM NaA M LSQWRF65VM NaA M...

Page 60: ...56 Unit Installation 3 LSQWRF35VM NhA M...

Page 61: ...57 Unit Installation 4 LSQWRF60VM NhA M...

Page 62: ...58 Unit Installation 5 LSQWRF130VM NhA M...

Page 63: ...59 Unit Installation...

Page 64: ...60 Unit Installation The electric wiring diagrams on the unit always prevail...