94

Test Operation, Troubleshooting and Maintenance

Replacement of the 4–way valve

Note: be sure power supply has been cut off and refrigerant has been reclaimed before replacement.

Steps

Image

Instructions

3. Replace it with a

new one and pipes.

• Do use the one with the same

model for replacement. The one

with different model can be used

after being approved by relative

technicians.

• Wrap it with wet cloth.

• Reconnect the main body with four

pipes as before.

• Solder the pipelines with a soldering

gun.

•

Do charge nitrogen during

desoldering.

4. Vacuum

the system

and recharge

refrigerant.

•

Keep the vacuum degree to -1.0bar.

Vacuuming period would be longer

for the repaired unit.

•

Charged refrigerant should be

the same as that stated at the

nameplate.

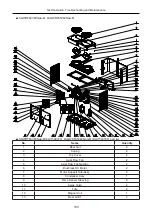

Replacement of the electric expansion valve

Note: check the whole system, pipelines and electric lines, cut off power supply and reclaim

refrigerant before replacement.

Steps

Image

Instructions

1. Reclaim

refrigerant and

remove the middle

panel.

• Cut off power supply of the unit.

•

Reclaim refrigerant.

•

Remove the middle panel.

Summary of Contents for LSQWRF35VM/NaA-M

Page 5: ...1 Product Product...

Page 18: ...14 Unit Control Unit Control...

Page 29: ...25 Unit Installation Unit Installation...

Page 58: ...54 Unit Installation 3 5 7 Electric wiring digram 1 LSQWRF35VM NaA M...

Page 59: ...55 Unit Installation 2 LSQWRF60VM NaA M LSQWRF65VM NaA M...

Page 60: ...56 Unit Installation 3 LSQWRF35VM NhA M...

Page 61: ...57 Unit Installation 4 LSQWRF60VM NhA M...

Page 62: ...58 Unit Installation 5 LSQWRF130VM NhA M...

Page 63: ...59 Unit Installation...

Page 64: ...60 Unit Installation The electric wiring diagrams on the unit always prevail...