Gree GMV6 DC Inverter VRF Units Service Manual

282

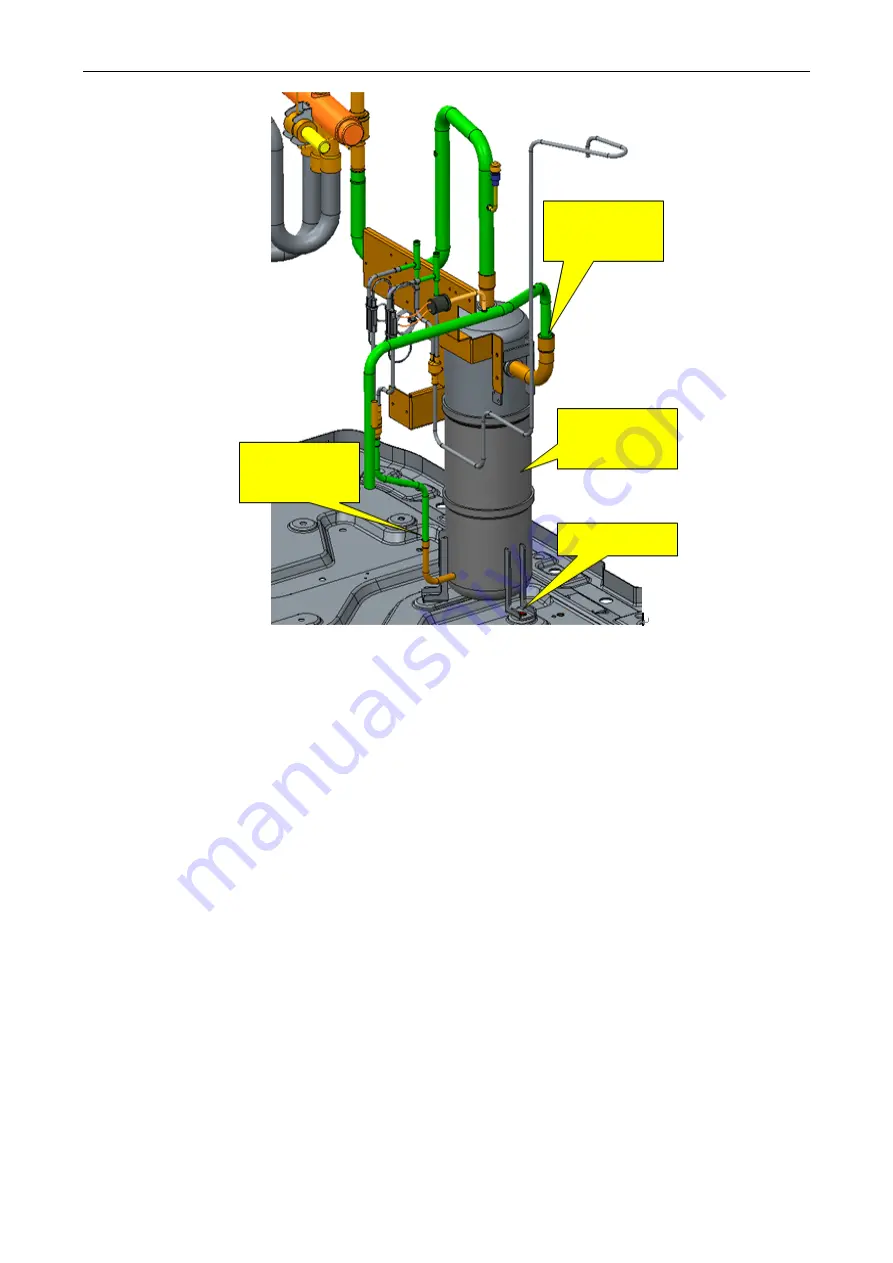

2. Weld the

connector of the

oil separator

1. Place the oil

separator in the

correct position

3. Fix the bolt

4. Weld the oil

return pipe

assembly

Step 13: System leakage inspection

1) Check each welding joints. Firstly, observe whether the welding joints are smooth and

whether there are obvious welding holes and other abnormal conditions.

2) Then, charge the unit system with high-pressure nitrogen for leak inspection. If it is only for

ODU maintenance, and it can be confirmed that there is no abnormality in the IDU system, only

charge the ODU with high-pressure nitrogen for leak inspection. Note that it is necessary to

simultaneously charge nitrogen from the high and low pressure sides. It is recommended to charge

the nitrogen valve at the same time with nitrogen. The nitrogen pressure should be greater than

20kgf. Use soapy water to check whether the unit system leaks, and focus on checking the service

joints.

3) Finally, charge the system with high-pressure nitrogen to keep the system pressure at

above 25kgf. Close the large and small unit valves and hold the pressure of the IDUs and ODU for

more than 12 hours. If the pressure does not change, start vacuuming. Otherwise, repeat the

aforementioned procedure until the leaking point is located.

When checking whether there is any change in the pressure of the system, it is necessary to

eliminate the temperature influence as the temperature changes by 1°C, and the pressure changes by

about 0.01 MPa. For example, when the temperature of nitrogen is 30°C, the pressure is 2.5 MPa. After

the pressure is held for more than 12 hours, the temperature becomes 25°C, the unit passes the test if

the pressure is above 2.43 MPa.

Summary of Contents for GMV-1015WM/G-U

Page 234: ...Gree GMV6 DC Inverter VRF Units Service Manual 232...

Page 264: ...Gree GMV6 DC Inverter VRF Units Service Manual 262...

Page 331: ...JF00304610...