❏

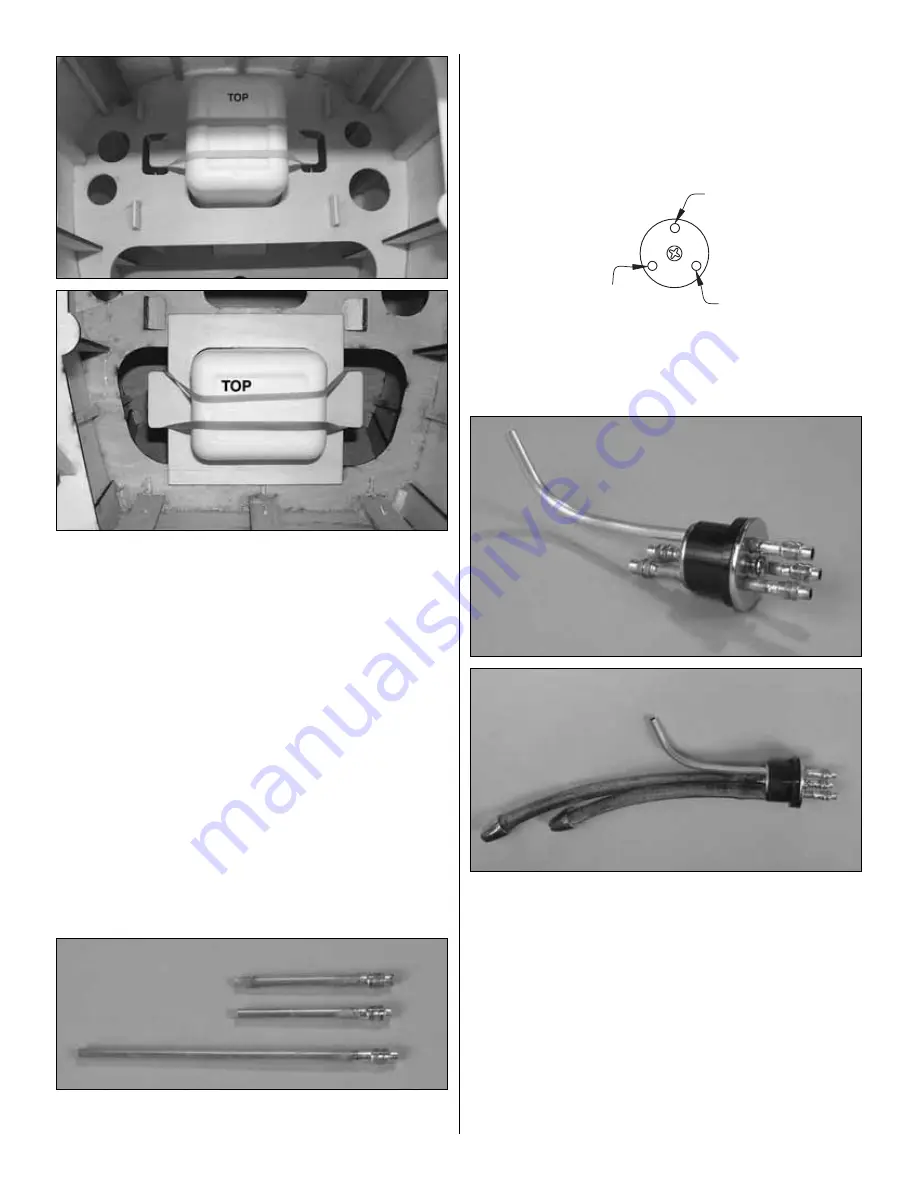

2. Note that there is an upper and a lower mounting

location for the fuel tank. Determine the mounting location for

the engine you will be using. The upper location will be used

for glow engines and most other engines. However, if using a

Fuji 50 engine or another type of engine that interferes with

the front of the fuel tank, mount the tank in the lower location

using the separate plywood fuel tank former. The lower fuel

tank location is also recommended if using the O.S. MAX

FT300 Twin due to the low placement of the carburetor. Notice

that, if using the lower location, the fuel tank will lie flat.

❏

3. Determine the type of fuel tank setup you will be using

and how many metal fuel tubes will be used in the stopper. The

suggested method is to use a three-line system—one line for

filling/emptying the tank, one line for the vent (or pressure if

using a glow engine) and one line for fuel pickup. This setup is

great for modelers who prefer not to use a fueling valve. It also

allows defueling with the model upright (as opposed to

defueling through the vent, which would require that the model

be turned upside-down to pump out all the fuel). If using a

fueling valve, a two-line system will be used.

❏

4. If using fuel line barbs (as recommended for gas

engines), replace the aluminum fuel tubes with 1/8" [3.2mm]

brass tubing (not included). Cut the brass tubes to the

correct length, then solder the barbs onto one end of the

tubes. The long brass tube will be bent upward for the vent

inside the tank.

❏

5. Assemble the rubber stopper with the metal plates,

screw and metal fuel tubes as shown in the sketch. (Refer to

this sketch when connecting the fuel lines later on.)

❏

6. Bend the vent tube upward. Solder on the remaining two

fuel line barbs—if used. Connect the pickup and fueling/de

fueling lines to the respective tubes on the back of the

stopper. Be certain to use the correct type of fuel tubing for the

type of engine (gas or glow) you are using. (Remember, Du-

Bro medium neoprene tubing is recommended for gas

engines because it fits tightly. Most types of gas-compatible

tubing expand when immersed in gas, so if the tubing does

not initially fit very tightly, it may loosen its hold and possibly

become disconnected from the clunk or the tubes in the

stopper). Connect a fuel line weight (“clunk”) to both lines. Be

certain the clunk on the end of the pickup line will not contact

the rear of the tank. Make the fueling/defueling line shorter

than the pickup line so they do not become entangled.

RIGHT SIDE

OF PLANE

FRONT VIEW

VENT

FUELING/

DEFUELING

PICKUP

LEFT SIDE

OF PLANE

30