❏

8. Remove the prop and spinner. Look inside the cowl

through the air inlets. Be certain you will be able to access the

five cowl mounting screws around the cowl ring with the

extended 3/32" [2.4mm] ball end hex wrench included with this

kit. (Note: After the cowl has been glued to the cowl ring,

access holes will be cut in the bottom of the cowl for the bottom

two screws). If any of the screws are concealed by the engine

(or will be concealed by the muffler when it is in position), those

screws will have to be relocated. If any screws do have to be

relocated, proceed to the next step. If not, proceed to step 11.

❏

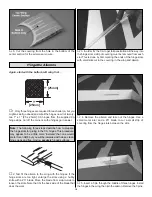

9. Any cowl mounting screws that cannot be reached

from outside the cowl with the extended wrench will have to

be relocated using the included 1/8" [3mm] plywood

mounting tabs and spacers. Glue the tabs and spacers to

the cowl ring where necessary so you will be able to access

the screws through the front of the cowl. Four sets of

mounting tabs are provided.

❏

10. Using the holes in the tabs as guides, drill 7/64"

[2.8mm] holes through F-1. Remove the cowl ring. Enlarge

the holes in F-1 only with a 9/64" [3.6mm] drill. Install new

4-40 blind nuts (included) by threading one onto a 4-40

pushrod. Add a drop of epoxy to the flange of the blind nut,

then, from inside the fuselage, guide the rod through the

hole in F-1. Pull the blind nut into the wood on the back of F-

1. Unthread the rod, then use a 4-40 x 1/2" [13mm] socket

head cap screw and several washers to fully draw the blind

nut all the way in. Install the rest of the blind nuts the same

way, then mount the cowl ring with the screws.

Okay, we’ve got the cowl ring mounted to the fuselage

and we know the cowl will align with the spinner, so it’s

time to glue on the cowl!

❏

11. Use a few paper towel squares dampened with

denatured alcohol to remove any residue left over from the

molding process from inside the cowl where the cowl ring

will go. Use coarse sandpaper to roughen the inside of the

cowl in the same area. This will increase the bonding

strength of the epoxy when gluing the cowl to the cowl ring.

❏

12. With the cowl ring mounted to the fuselage with the

screws, slide the cowl into position. Mount the prop and

spinner. Align the cowl with the spinner just as was done

before (providing adequate clearance). Stand the fuselage

vertically on the trailing edge of the fin. Rest the fuselage

against your workbench or other stable object.

❏

13. Use a 12" [300mm] strip of basswood, hard balsa or

something similar that can be used to apply epoxy to the

cowl ring down inside the cowl. Round one end of the stick.

Mix up a batch of 30-minute epoxy and microballoons. Be

certain to use plenty of microballoons to thicken the epoxy

so it does not leak past the cowl ring and get onto the

fuselage (a one-to-one ratio is appropriate). Immediately

proceed to the next step.

21