❏

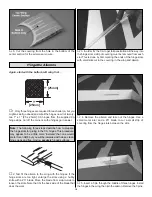

1. Use 30-minute epoxy to glue together the three

plywood aft bottom wing joiners and the three plywood

forward bottom wing joiners. Clamp the joiners together

and wipe away excess epoxy. (Steel spring clamps are ideal

for holding the joiners together.) Note: If you happen to

notice that one of the joiners is thinner than the other two, it

doesn’t matter where in the “stack” it is positioned.

Now the joiners will be ready when it’s time to glue together

the bottom wings.

Start with the bottom, left wing panel first so yours

looks like the photos the first time through.

❏

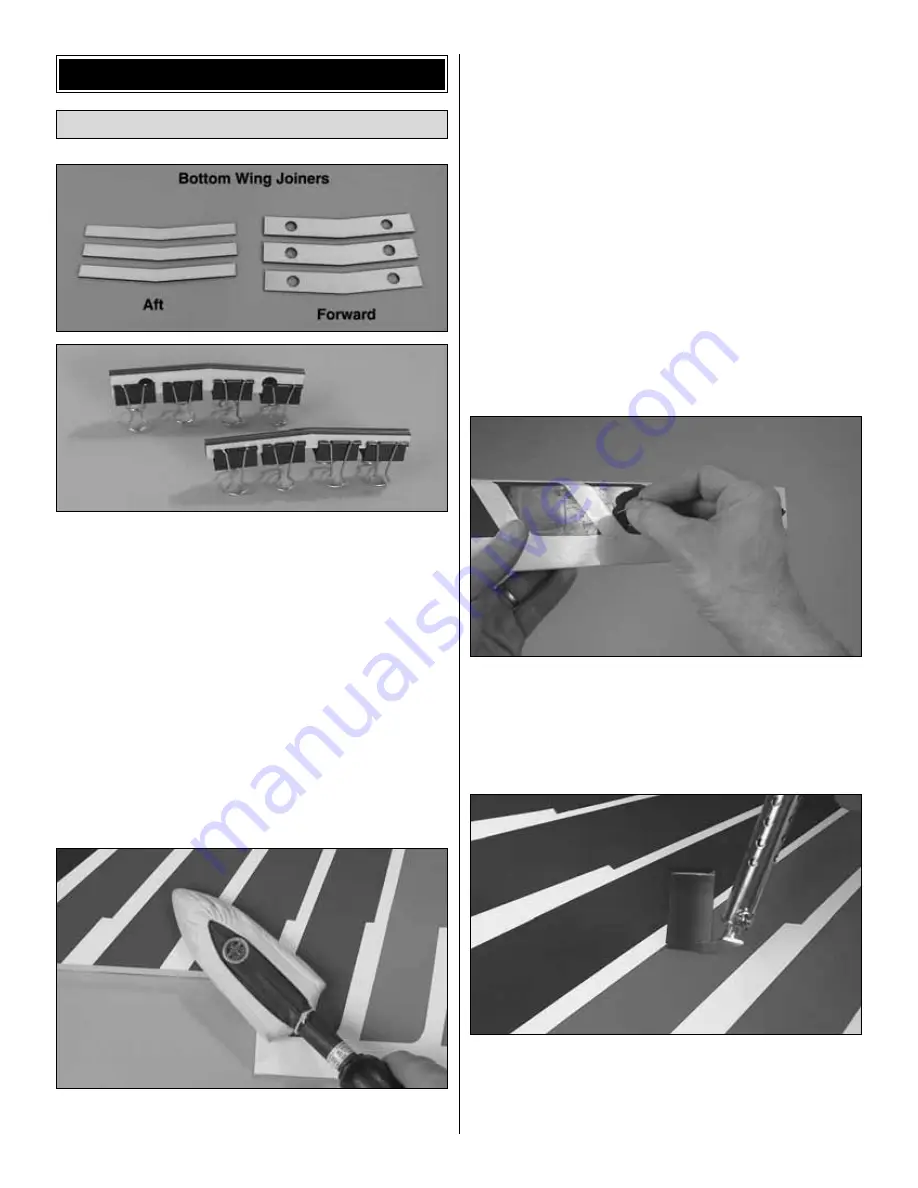

2. Carefully remove the masking tape holding the aileron

to the wing. Residual adhesive from the tape may be

removed with naphtha lighter fuel or denatured alcohol.

❏

3. Use a covering iron with a covering sock to thoroughly

bond the covering to the structure and remove any wrinkles in

the wing and aileron. The best way is to glide the iron over the

covering until the wrinkles disappear, then push down on the

iron to bond the covering to the wood. If you come across a

wrinkle that won’t go away, the balsa in that area may be

bending inward. If this is happening, do not apply pressure.

Simply let the heat of the iron shrink the covering. If the

wrinkles momentarily disappear, then immediately reappear,

the iron may be too hot, thus causing air bubbles. Lower the

temperature of the iron or use a sharp #11 blade to puncture

several small holes in the covering, then reheat. The

suggested iron temperature is around 360 degrees F. Hint:

Any MonoKote pigment that gets smeared on other areas

may be removed with a tissue lightly dampened with

MonoKote Trim Solvent or CA debonder. Trim solvent and

debonder are powerful, so using too much may loosen the

covering if it gets under the seams. To avoid this, immediately

wipe away excess solvent using another tissue dampened

with household spray cleaner (Windex

®

, Formula 409

®

).

Suggestion: Before tightening the covering over the ailerons,

use a pin to poke six to eight holes in the covering over each

lightening hole on the bottom. (Where possible, poke the holes

in colored areas where there are two layers of covering.) When

heating the covering, expanding air will escape through the

holes, thus allowing the covering to fully tighten.

❏

4. While you’ve got your covering tools out, use a

straightedge and a hobby knife to cut the covering 1/8"

[3mm] inside the edges of the opening in the bottom of the

wing panel for the aileron servo. Use a trim seal tool to iron

the covering down inside the edges of the opening.

Prepare the Wings

ASSEMBLE THE WINGS

9