❏

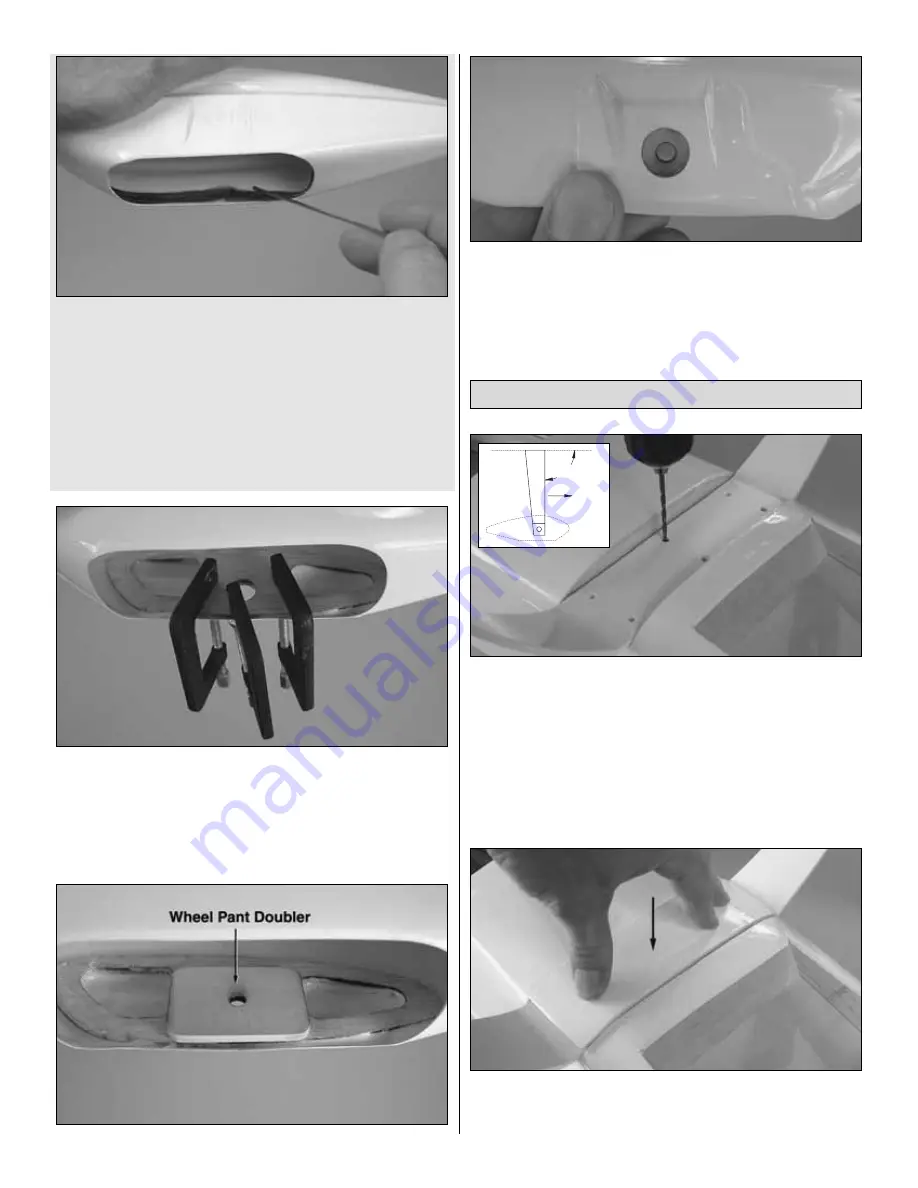

E. Use your fingers or a wire to lift the epoxy-soaked

carbon fiber swatch from the plastic bag and place it inside

the opening of the wheel pant. Use the wire to maneuver the

swatch into position.

❏

F. When the swatch is pretty much where you want it,

dip your finger in denatured (or rubbing) alcohol and smooth

it all out.

❏

G. Clean up with alcohol and allow the epoxy to harden.

❏

6. Bevel the edges around the side of the plywood wheel

pant braces that contact the inside of the pants. Use a

generous amount of 30-minute epoxy mixed with microballoons

to glue one brace to the inside of each wheel pant as shown.

Make sure the hole in the braces aligns with the hole the wheel

pants. Wipe away excess epoxy before it hardens.

❏

7. Glue the plywood wheel pant doubler to the wheel pant

brace inside each pant. The 3/16" [4.8mm] hole in the doubler

must be centered over the 1/2" [13mm] hole in the pant (the

wheel axles, cut to the correct length as shown on page 27,

could be used to align the holes).

❏

1. Noting which direction is forward as shown in the sketch,

center the main landing gear on the landing gear plate on the

bottom of the fuselage. Use the holes in the gear as a guide to

drill 1/8" [3.2mm] holes through the bottom of the fuselage.

❏

2. Bolt the landing gear to the fuselage with six #8 x 5/8"

[116mm] screws. IMPORTANT! Remove the landing gear

and harden the holes in the landing gear plate with a few

drops of thin CA. Remount the gear.

❏

3. Position the balsa landing gear cover over the

landing gear in the fuselage. Press down on the cover to

mark the heads of the screws into the cover.

Prepare the Landing Gear

25

90˚

FORWARD