Page 3431

1. Check whether the magnetic tile of the

magneto

rotor is cracked or damaged

, and if so,

replace it with a new magneto rotor.

2. Check whether the magneto stator coil is

black, if so, replace it with a new magneto stator.

Check the balance of the main and driven gears

1. Check whether the balance main and

driven gears are worn or damaged.

2. Whether the buffer spring of the balance

driven gear is broken, if it is broken, it needs to be

replaced with a new gear

.

Left Body Oil Pump Inspection

1. Check the left body oil pump rotor

assembly for wear and damage;

2. Check the left body oil pump cover for

wear and damage.

Installation of the left body oil

pump

1. Install the left body oil pump pin (1) into

the corresponding hole of the oil pump shaft, and

then install the left body oil pump (2) into the

corresponding hole of the left body;

2. Fasten the left cover plate (4) of the oil

pump with 3 bolts M5

×

1 2(3).

Notice:

1. When installing the oil pump rotor, the

marked surfaces of the inner and outer

rotors should face the same direction;

2. Tightening torque of the bolts of the left

oil pump cover plate: 7

~

9N m;

3. After tightening, check whether the oil

pump shaft rotates flexibly.

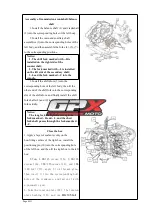

Installation of balanced main and

driven gears

1. First install the NC250 crankshaft sleeve

(5) on the balance shaft, then install the NC250

balance shaft flat key (6) into the keyway of the

balance shaft, and finally install the balance driven

1

2

4

3

5

6

7

8

6

9

11

10

13

1

2

When balancing the main and driven teeth, the timing marks of the

balanced main and driven teeth should be aligned, that is, the teeth with the

timing marks of the balancing main and driven teeth should mesh with each

other.

14

15

1

7

16