Page 3531

gear assembly (7) on the balance shaft ;

2. First install the balance driving gear (8) on

the left crank, then install the NC250 balance shaft

flat key (6) into the keyway of the crankshaft, and

then install the NC450 crankshaft timing sprocket

(9) on the left crank;

Notice:

When installing the balance master and

driven teeth, the timing marks of the

balance master and driven teeth should be

aligned, that is, the teeth with the timing

marks of the balance master and driven

teeth should mesh with each other.

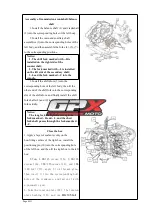

3. Put the balance driving gear nut lock

washer (10) and the CB125 clutch disc washer

(11) on the crankshaft timing driving sprocket (9)

and the balance driven gear assembly (7)

respectively, and lock them on the balance shaft.

Nut M24

×

1(12) Clutch lock nut M16

×

1(13)

Apply 3~4 threads of thread tightening glue, then

install it on the crankshaft and balance shaft and

fasten it.

The tightening torque of the balance

driven gear lock nut: 80

~

90N

·

m, and the

tightening torque of the balance driven gear

lock nut: 115

~

125N

·

m.

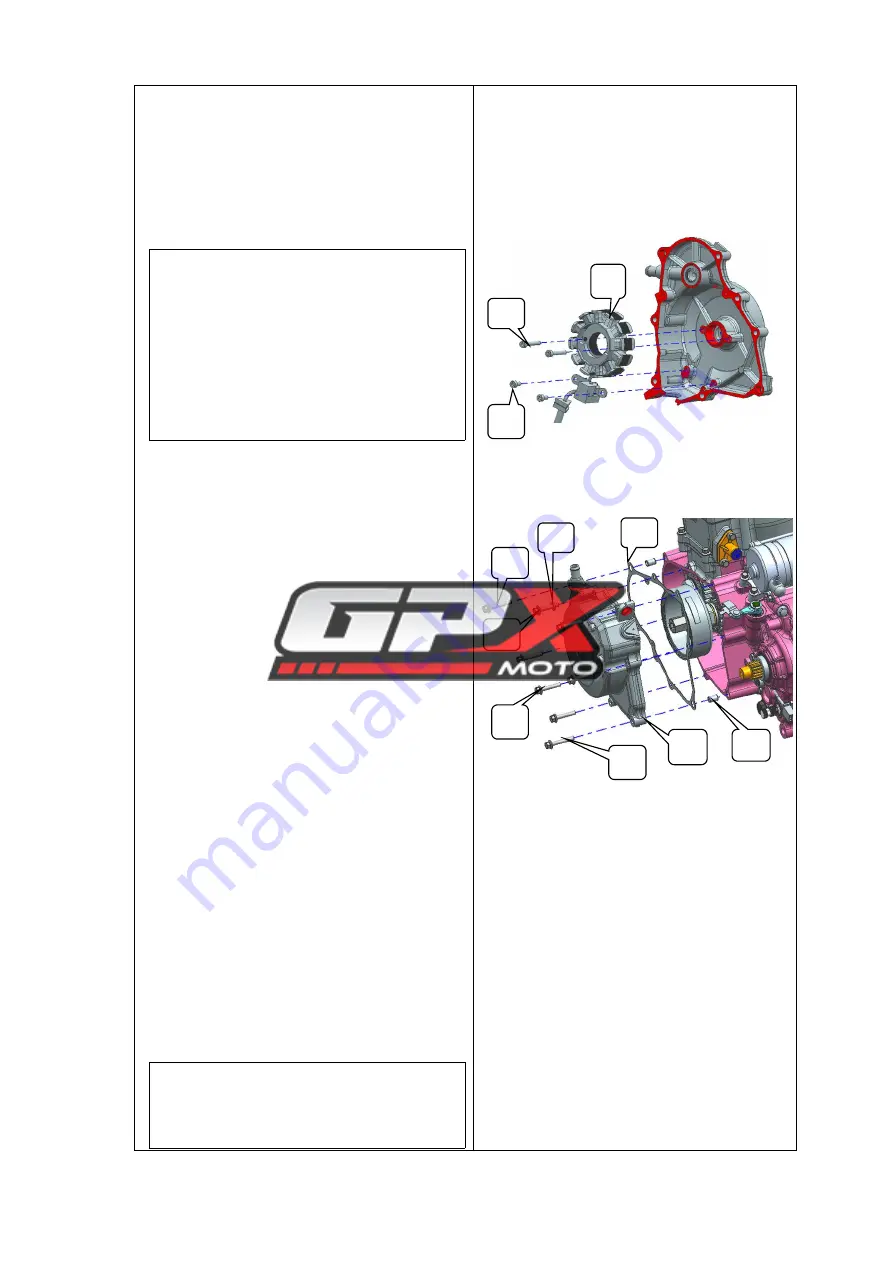

Installation of the magneto rotor

1. One magneto semicircular key (14),

installed in the semicircular keyway of the

crankshaft;

2.

Install the magneto rotor (15) on the left

crank, then apply 3 to 4 threads of thread

tightening glue on the magneto nut (16), then

install it and the washer (17) on the left crank and

tighten.

Notice:

Tightening torque of magneto rotor lock

nut: 80

~

90N

·

m.

19

20

1

8

21

22

23

24

24

25

26

27