Instruction Manual ZS100T, ZS150T & ZS200T Series II (MAM-870) Senator Industrial Air Compressors

26

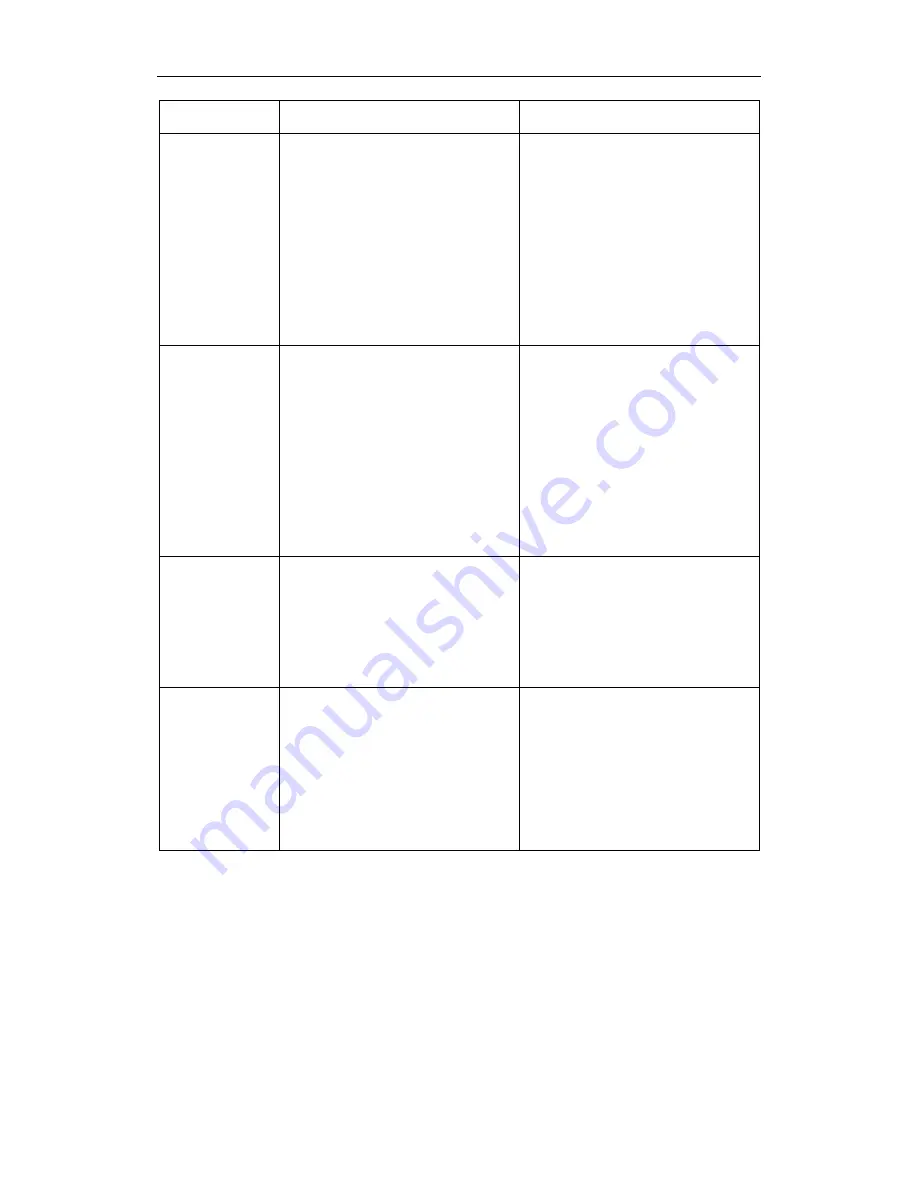

Symptom

Possible Cause

Corrective Action

System pressure

(tank pressure) is

too high.

1.

Unloading parts (such as solenoid

valve ‘C’ in air inlet control valve,

vent valve, etc.) are faulty.

2.

Pressure settings are too high.

3.

Leakage in control air piping.

4.

The filter in control air piping is

blocked.

5.

Oil-air separator is blocked.

6.

Minimum pressure valve is faulty.

7.

Pressure sensor is faulty.

1.

Check unloading parts for normal

operation.

2.

Check the controller’s pressure

settings.

3.

Check and rectify leakage.

4.

Clean or replace filter assembly.

5.

Replace oil-air separator.

6.

Check and repair minimum

pressure valve.

7.

Check or replace pressure sensor.

Compressed air

has relatively high

oil content and oil

refilling period is

shortened.

1.

Oil addition is excessive and oil

level in oil-air tank is too high.

2.

Filter or orifice in oil return pipe is

blocked.

3.

Filter element or packing washer

in oil-air separator is damaged.

4.

Oil return pipe in oil separator

element is damaged.

5.

Leakage in oil piping system.

6.

Oil grade is poor causing

excessive foaming.

1.

Check oil level and drain out any

excess.

2.

Clean filter element and orifice.

And if necessary, replace them.

3.

Check oil-air separator. If it is

damaged, replace it.

4.

Replace oil return pipe.

5.

Check oil piping system and

eliminate leakage.

6.

Replace oil with correct grade.

Oil mist leaks out

of air filter during

shutdown.

1.

Before shutdown, no unloading is

performed or unloading period is

too short.

2.

Minimum pressure valve is faulty.

3.

Venting of oil-air tank is

incomplete.

1.

Check air inlet control valve.

Check electrical circuits such as

shutdown time delay, etc.

2.

Check and repair minimum

pressure valve.

3.

Check vent valve.

The switching

between

unloading and

loading is too

frequent.

1.

Air piping leakage.

2.

The difference between the unload

and load pressure settings is too

small.

3.

Air consumption is unstable.

1.

Check and rectify air leakage.

2.

Check the controller’s pressure

settings.

3.

Increase the air storage capacity.

If necessary, install pressure

regulating valve downstream from

the air tank.

Summary of Contents for MAM-870

Page 2: ......

Page 8: ...Instruction Manual ZS100T ZS150T ZS200T Series II MAM 870 Senator Industrial Air Compressors 4...

Page 39: ......

Page 40: ......

Page 41: ...INSTRUCTION MANUAL MAM 870 COMPRESSOR CONTROLLER...

Page 42: ......

Page 58: ...NOTES...

Page 59: ......

Page 60: ......