Instruction Manual ZS100T, ZS150T & ZS200T Series II (MAM-870) Senator Industrial Air Compressors

25

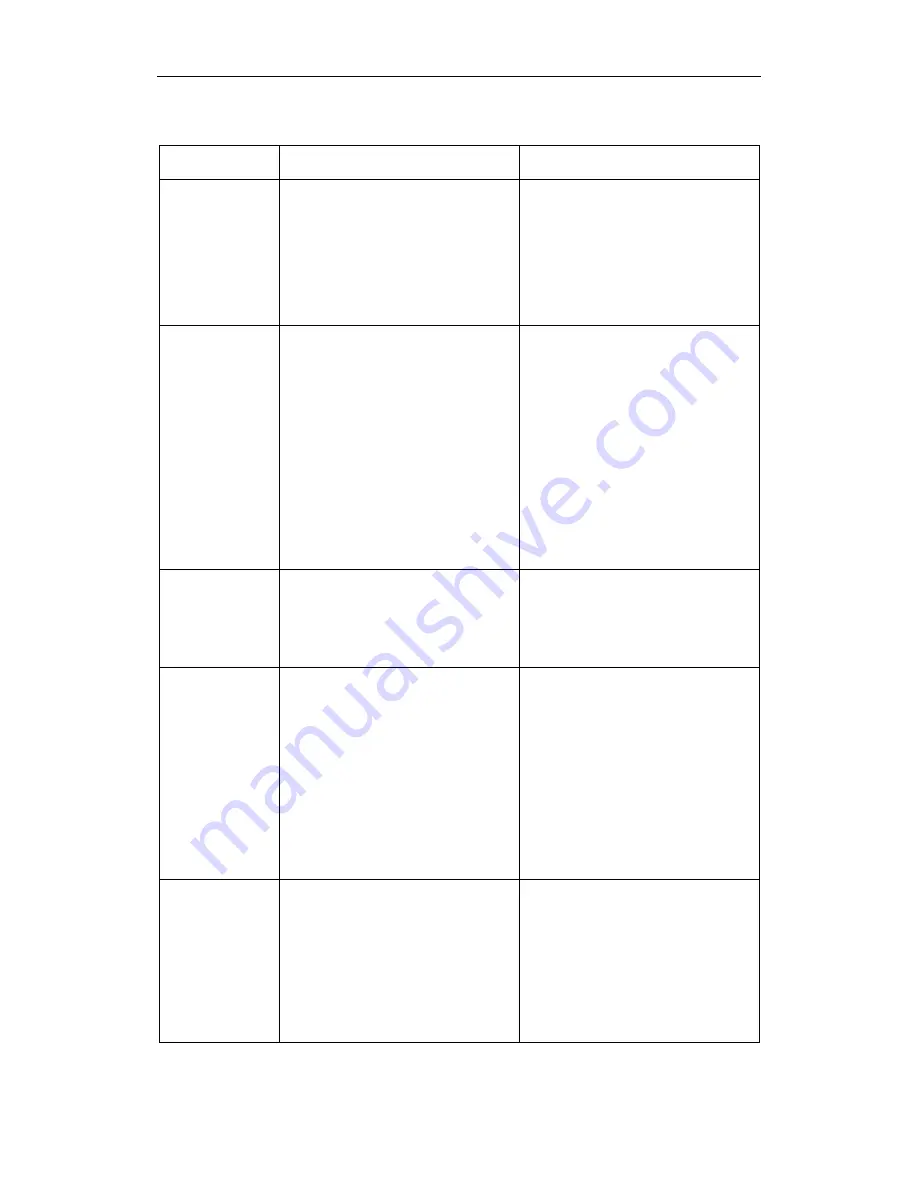

5.2 Troubleshooting Chart

Symptom

Possible Cause

Corrective Action

Compressor fails

to start up.

1.

Fuse is ruptured.

2.

Power supply voltage is too low.

3.

Phase-loss or error-phase.

4.

Loose wiring or poor contact.

5.

Motor failure.

6.

Air end failure.

1.

Investigate cause and replace fuse.

2.

Investigate and rectify electricity

supply.

3.

Restore phase loss or re-connect

the wire.

4.

Check and tighten all connections.

5.

Repair or replace motor.

6.

Repair or replace air end.

Too high air

discharge

temperature

(≥105°C).

1.

Insufficient lubricating oil.

2.

Too high ambient temperature.

3.

Oil cooler fins are blocked.

4.

Oil filter is blocked.

5.

Thermostatic valve is faulty.

6.

Incorrect grade of lubricating oil.

7.

Cooling fan is faulty.

8.

Temperature sensing element is

damaged.

1.

Check oil level in oil-air tank.

2.

Improve ventilation conditions and

reduce room temperature.

3.

Clean oil cooler fins.

4.

Replace oil filter.

5.

Check whether oil is cooled down

via oil cooler. If not, repair or

replace thermostatic valve.

6.

Change to correct grade of

lubricating oil.

7.

Repair or replace cooling fan and

fan motor.

8.

Check or replace temperature

sensing element.

Too low air

discharge

temperature

(≤75°C).

1.

Very low ambient temperature.

2.

Thermostatic valve is faulty.

3.

Temperature sensor is incorrect.

1.

Reduce radiating area of cooler.

2.

Repair or replace thermostatic

valve.

3.

Check and replace temperature

sensing element.

Air supply

pressure is below

rated discharge

pressure.

1.

Pressure settings are too low.

2.

Air consumption of the user is

higher than air supply amount.

3.

Air filter is blocked.

4.

Inlet valve isn’t opening fully.

5.

Pressure sensor is faulty.

6.

Minimum pressure valve is faulty.

7.

Oil-air separator is blocked.

1.

Check the controller’s pressure

settings.

2.

Reduce air consumption and/or

check air piping system for

leakage.

3.

Clean or replace air filter element.

4.

Check the action of inlet valve.

5.

Check or replace pressure sensor.

6.

Check and repair minimum

pressure valve.

7.

Check and replace oil-air

separator.

Air supply

pressure is above

the setting of

unloading

pressure.

1.

Pressure settings are too high.

2.

Unloading parts (such as solenoid

valve ‘C’ in air inlet control valve,

vent valve, etc.) are faulty.

3.

Leakage in control air piping.

4.

The filter in control air piping is

blocked.

5.

Pressure sensor is faulty.

1.

Check the controller’s pressure

settings.

2.

Check unloading parts for normal

operation.

3.

Check and rectify leakage.

4.

Clean or replace the filter

assembly.

5.

Check or replace pressure sensor.

Summary of Contents for MAM-870

Page 2: ......

Page 8: ...Instruction Manual ZS100T ZS150T ZS200T Series II MAM 870 Senator Industrial Air Compressors 4...

Page 39: ......

Page 40: ......

Page 41: ...INSTRUCTION MANUAL MAM 870 COMPRESSOR CONTROLLER...

Page 42: ......

Page 58: ...NOTES...

Page 59: ......

Page 60: ......