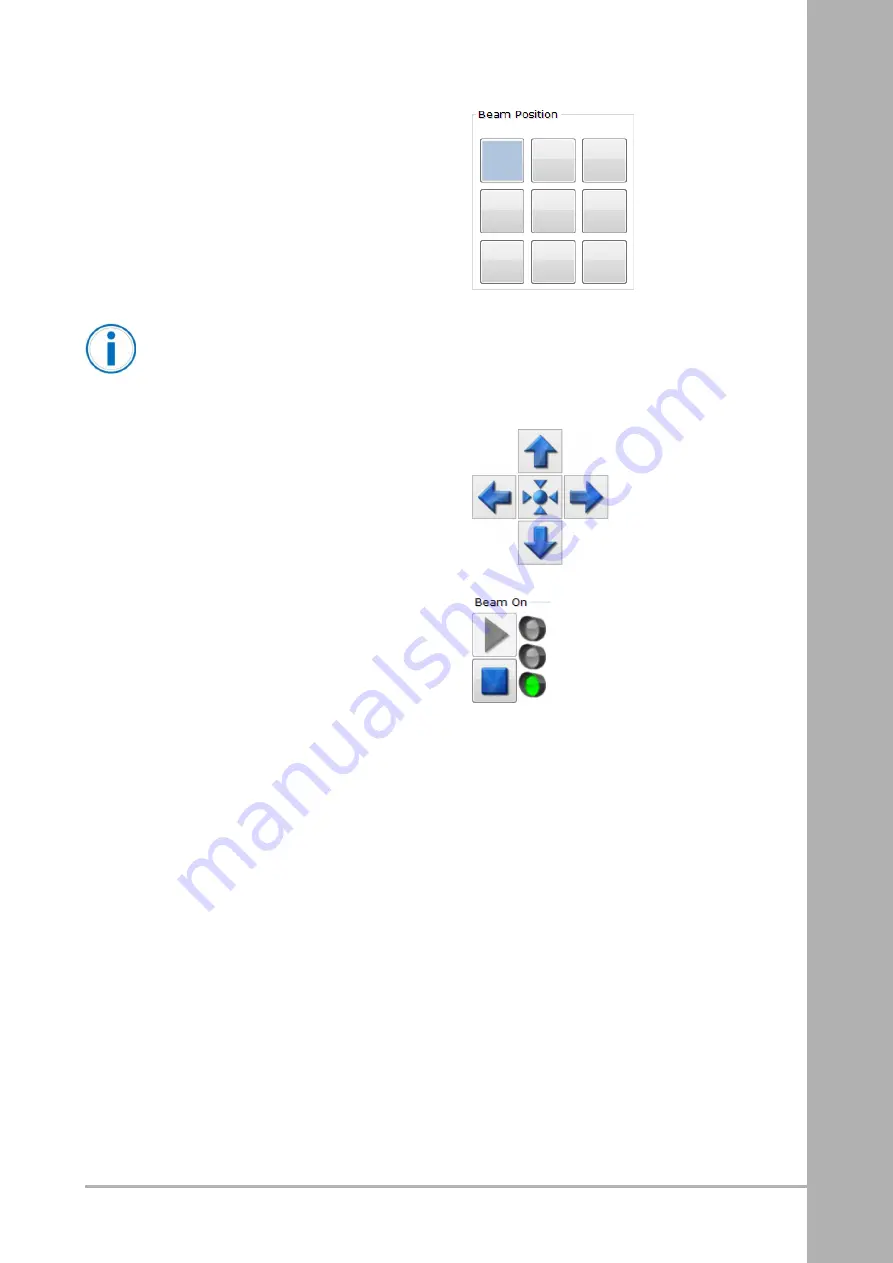

7. Press a square to choose a beam position.

N

No

otte

e

All nine beam positions have to be aligned individually.

8. Observe the beam for flickering through the view-

port. A flickering might be seen as two spots alter-

nating close to each other.

9. Press the arrows (Up-Down / Left-Right) until the

flickering stops and the two spots coincide as one.

10. Perform this procedure for all the nine beam

positions.

11. Press S

Stto

op

p to deactivate the beam.

12. Press S

Sa

avve

e to save the alignment.

02

OM-710430

en-GB

129

Summary of Contents for ArcamEBM Spectra H

Page 1: ...Original language 02 OM 710430 en GB O OM M Operation Manual Spectra H...

Page 2: ...This page is intentionally left blank...

Page 4: ...Table of contents ii 02 OM 710430 en GB This page is intentionally left blank...

Page 6: ...Table of contents ii 02 OM 710430 en GB This page is intentionally left blank...

Page 8: ...This page is intentionally left blank 2 Revision Notes 4 02 OM 710430 en GB...

Page 24: ...5 Safety 412532 Jokab Safety Eden Eva 105261 Light curtain 20 02 OM 710430 en GB...