•

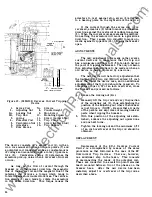

shaped section which is easily accessible to a

small, open end, 1/4 inch wrench. Two cantilever

springs, which bear on each end against a portion

of the hexagon section of the pin, lock the ad

justing pin in place and provide index stops for

the process of adjustment. The right hand hexagon

shaped end of the pin is numbered from 1 to 6,

which provides a reference for making wipe

adjustments.

When contacts are to be adjusted, the recom

mended procedure is as follows:

1.

With the breaker in the open position and using

the numbers on the right end of each adjusting

pin as a reference, set each pin in the same

position.

In

many cases

�

the number 3 is a

good beginning point. The proper view of the

number on the adjusting pin is obtained by

viewing the breaker from the front and the

adjusting pin from approximately a 15 degree

angle with respect to the movable contacts.

Note that the numbers on the pin are not in

numerical sequence as the pin

is

rotated.

2 .

By measurement, establish the position of the

front surfaces of the stationary contacts with

reference to the steel arc runners above and

behind the contacts.

3. Close the breaker, and establish the amount

of wipe by again measuring as in step two,

and comparing the measurements with those

taken with the breaker open.

4. If any set of contacts lead or lag the others,

open the breaker and advance or retard the

pin to the next higher or lower

number. Moving the adjusting pin to a higher

number will increase the contact wipe and

moving to a lower number will decrease the

contact wipe.

NOTE: No attempt should be made to move

the adjusting pin when the breaker is closed.

Besides being more difficult, the additional

force required to move the pin will tend to

round off the flats of the hex section of the pin.

5. When all the contacts have the recommended

wipe of 3/32 to 5/32 of an inch, the contact

adjustments are complete.

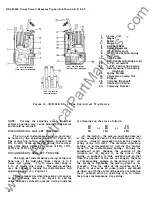

CONTACT REPLACEMENT

Figure 3

The normal situation that will exist in the

matter of contact replacement will call for re

placement of all the movable and stationary con

tacts at the same time. This will be the case

where long use of the breaker in service has

resulted in extensive wear or erosion of the

silver alloy contact tips.

A commonly used

" rule of thumb" is that contact replacement is

indicated if less than one-half of the original

thickness (1/8 of an inch) of the contact tip

material remains.

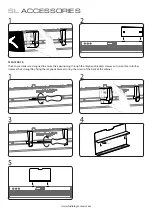

GENERAL PREPARATION

1.

Remove arc quencher retainer (1 )

,

Fig\lre 5

bY. loosening the two captured nuts with a

7716" wrench.

2 .

Lift off the three arc quenchers.

3. Remove the U shaped insulation (5) Figure 3

from each pole by 'lifting it and disengaging

the rivet heads thru the keyholed slots in the

insulation.

4.

As an aid to future reassembly of the movable

contacts, note the position of all stationary

insulation barriers with respect to barriers

mounted on the cross bar.

REMOVAL OF MOVABLE CONTAC TS

( 18) Figure 3.

1. Screw the threaded end of the steel rod

lightly into pivot pin (11) on the right pole.

2. With a pair of long nosed pliers, unhook

safety pin type spring clip (9) and extract

pin (11) and remove spring clip (9).

3 . Grasp movable contact assembly and remove

it from its seat on the cross bar.

4.

Repeat procedure 1,

2,

and

3

above on the

left pole.

5. Move the cross bar downward to disengage

it

from the contact wipe adjusting pin (15)

on the center pole, then move the cross bar

toward the front of the breaker.

6.

Remove the split pin retaining the center

pole pivot pin.

7.

Remove the pivot pin and movable contact

assembly.

REMOVAL OF STATIONARY CONTACTS

(2 1) Figure 3 .

1. Slip the blade of a heavy screw driver between

the two upper contacts and force the contacts

toward their pivot point sufficiently far to

disengage the contact stop surface from the pin.

2 .

The contact can then b e removed by disengaging

the end of the contact from its spring.

3.

The two lower contacts can be similarily

removed.

REPLACE MENT OF STATIONARY CONTACTS

(2 1) Figure

3 .

1. Coat the contact pivot area only of each of

the four contacts with a thin coat of D50H47

grease. Use only D50H47 grease.

2 .

Note the difference between the two types of

9

www

. ElectricalPartManuals

. com