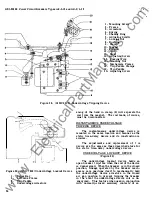

Figure 1 0. (8024842) EC-2 Overcurrent Trip

1 . Series Coil

2.

Trip Adjustment Screw

3. Opening for Time Adjustment

4.

Pickup Indicator

&

Calib. Plate

5.

Pickup Adjustment Knol;>

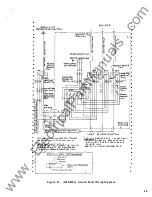

The long-time delay tripping feature can be

supplied with any one of three time-current char

acteristics which correspond to the NEMA stand

ards maximum, intermediate and minimum long

time delay operating bands . These are identified

as 1A, 1B and 1 C characteristics, respectively.

Approximate tripping time for each of these, in

the same order are 30,

1 5

and

5

seconds at 600%

of the pick-up value of current. (See time-current

characteristic curves 286B201A, B, and

C).

The tripping time may be varied within the

limits shown on the characteristic curves by turning

the time adjustment screw

(5),

Figure 1 1. Turning

in a clockwise direction increases the tripping time;

Figure 1 1. (8024843) EC-2 Overcurrent Trip With

Cover Removed.

1 . Instantaneous Calibration Spring

2. Movable Nut (Index Pointer)

3. Time-Delay Calibration Spring

4. Instantaneous Pickup Adjustment Screw

5.

Time-Delay Adjustment Screw

6. Oil Dashpot

7. Dashpot Arm

8. Connecting Link

9. Instantaneous Pickup Calibration Marks

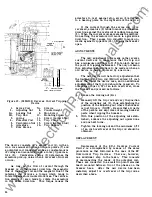

counter-clockwise motion decreases it. The dash

pot arm (7), Figure 1 1 is indexed at four points,

maximum - 2/3 - 1/3 - minimum from the left,

as viewed in Figure 1 1. When the index mark on

the connecting link (8), Figure 1 1 , lines up with a

mark on the dashpot arm, the approximate tripping

time as shown by the charaCteristic curve is in

dicated

•

The 1A and 1B characteristic devices are

shipped with this setting at the 2/3 mark and the

lC characteristic at the 1/3 mark. The standard

characteristic curves are plotted at the same

settings.

Time values are inversely proportional to

the effective length of the dashpot arm. There

fore, the linkage setting that gives the shortest

time value is the one at which dimension "A"

Figure 1 1, is greatest.

The time adjustment

screw

(5),

Figure 1 1 , may be turned by inserting

a Phillips head screwdriver through the hole in

the front of the case, but if it is desired to relate

the linkage setting to the index marks on the

linkage it will be necessary to remove the case.

This may be done by removing the two mounting

screws, one on each side of the case, which

may be taken off without disturbing the trip unit

itself.

2 1

www

. ElectricalPartManuals

. com