ANITA ©

29

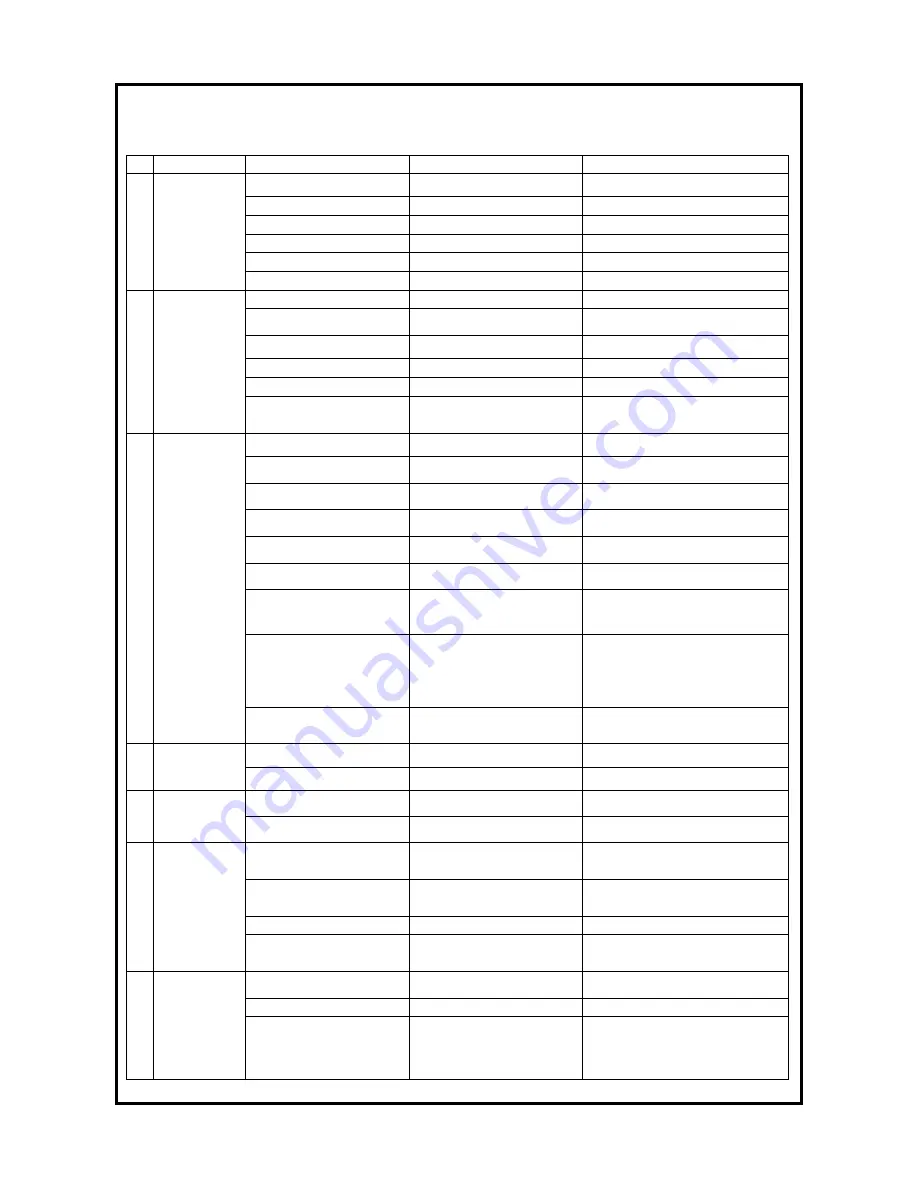

5) Cause of troubles and troubleshooting

1) Sewing machine troubleshooting

No

Symptom

Checkpoints

Root cause

Corrective action

Direction and height of needle

Needle is inserted into wrong

position.

Reinsert the needle correctly.

Needle

Needle is bent.

Change the needle.

Bad timing of feed dog.

Adjust the timing of feed dog.

1

Needle breaks

Ascending level of needle bar

Bad timing of needle and hook.

Adjust the timing of needle and hook.

Height of needle

Bad timing of needle and hook.

Adjust the timing of needle and hook.

Gap between needle and hook Bad timing of needle and hook.

Adjust the timing of needle and hook.

Threading method

Wrong threading.

Thread the needle correctly.

Needle

Bent needle or broken needle

tip.

Change the needle.

Direction and height of needle

Needle inserted in the wrong

position.

Insert the needle correctly.

2

Thread breaks

Upper thread tension

Too tight upper thread tension.

Reduce tension of upper thread.

Lower thread tension

Too loose lower thread tensin.

Reduce tension of lower thread.

Working capacity of take-up lever

Loose upper thread.

Adjust take-up lever spring.

spring

Direction and height of needle

Needle inserted in the wrong

position.

Reinsert the needle in the right direction.

Needle

Bent needle or broken needle

tip.

Change the needle.

Threading

Thread passing at wrong

position.

Change the needle.

Ascending level of needle bar

Wrong timing of needle and

hook.

Adjust the timing of needle and hook.

Height of needle bar

Wrong timing of needle and

hook.

Adjust the timing of needle and hook.

Gap between needle and hook

Wrong timing of needle and

hook.

Adjust the timing of needle and hook.

3

Stitch skips

Remaining length of upper

thread

Adjust the thread adjusting device.

is short.

Due to bobbin racing during

Racing-proof spring

trimming, lower thread dropping

Change the racing protection

of bobbin case

from bobbin case becomes too

spring.

short to go up.

Take-up lever spring

Unable to lift lower thread due to Adjust the working capacity

weak take-up lever spring.

of take-up lever spring.

4

Upper thread

Too tight upper thread tension.

Reduce tension of upper thread.

does not sink.

Too loose lower thread tension.

Increase tension OF lower thread.

5

Lower thread

Too tight upper thread tension.

Too strong lower thread tension.

does not sink.

Increase tension of upper

thread.

Decrease tension of lower thread.

Tension of fixed blade

Tension not aligned between

Adjust tension of movable and fixed blade.

movable and fixed blade.

Trimming

Edge of movable and fixed

Abrasion in blade groove of

Replace movable and fixed blade.

errors

blades

movable and fixed blade.

Direction of needle

Wrong needle insertion.

Reinsert the needle correctly.

Check the crossing of trimmer Insufficeient crossing quantity of Adjust the stroke of movable and

cam notch mark and blade

movable and fixed blade.

fixed blade.

Upper thread

Too strong upper thread

tension.

Adjust tension of upper thread.

is pulled out

Too thick a needle for thread.

Check thickness of needle.

7

when sewing

Take-up lever pulls out the

upper

Adjust the up-stop position

commences.

Check th up-stop position

thread because the needle up

of needle.

of needle

and down position is too high.

Summary of Contents for GF-1116 Series

Page 30: ...ANITA 30...