ANITA ©

22

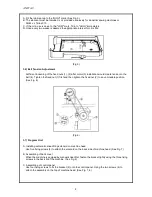

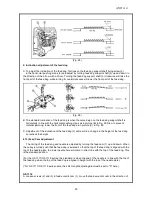

4.14) Adjustment of Needle Movement (GF-1117/GF-1118 series)

1. The standard position is when the needle feed connecting rod (2) is positioned at the carved sign

marked on the horizontal pushing crank (back)(1).

2. To increase the feed dog movement over the needle movement, loosen nut (3) and adjust the

needle feed connecting rod (4) in (a) direction and then tighten nut (3). The feed dog movement can

increase about 20% in excess of the needle movement and this adjustment is especially effective

for slippery material or thick material, which are susceptible to jams

3. In contrast, turning the needle feed connecting rod (2) in (b) direction would decrease needle

movement such that it would be smaller than the feed dog movement. (See Fig 32)

(Fig. 32)

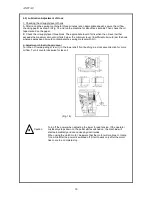

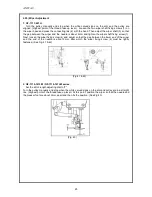

4.15) Timing Adjustment of Trimmer

1. Turn the pulley (1) manually on the pulley and the carved sign (3)

on the arm.

(Fig. 33)

2. Push the trimming lever (5) so that the thread trimming knife (7) on the hill of the movable knife (6

is about 1~1,5mm more protruded than the end point of the fixed blade (8).

3. Push the trimming solenoid shaft (10) manually while the trimming cam fixing screw (9) is loose.

(At this point, the appropriate distance between the initial trimming cam (11) and the roller single

screw (12) is 0,5mm.)

Summary of Contents for GF-1116 Series

Page 30: ...ANITA 30...