4. INSTALLATION

36

smooth as possible to provide an undis-

turbed flow of water around the transduc-

er. The fairing block should be smaller

than the transducer itself to provide a

channel to divert turbulent water around

the sides of the transducer rather than

over its face.

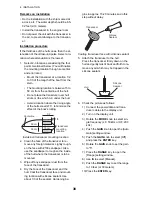

Construction of fairing block

3. Drill a hole just large enough to pass the

threaded stuffing tube of the transducer

through the hull, making sure it is drilled

vertically.

4. Apply a sufficient amount of high quality

caulking compound to the top surface of

the transducer, around the threads of the

stuffing tube and inside the mounting hole

(and fairing blocks if used) to ensure wa-

tertight mounting.

5. Mount the transducer and fairing blocks

and tighten the locknut. Be sure that the

transducer is properly oriented and its

working face is parallel to the waterline.

Typical thru-hull mount

transducer installations

Note:

Do not over-stress the stuffing tube and

locknut through excessive tightening, since

the wood block will swell when the boat is

placed in the water. It is suggested that the

nut be tightened lightly at installation and re-

tightened several days after the boat has

been launched.

Transducer preparation

Before putting the boat in water, wipe the face

of the transducer thoroughly with a detergent

liquid soap. This will lessen the time neces-

sary for the transducer to have good contact

with the water. Otherwise the time required for

complete "saturation" will be lengthened and

performance will be reduced.

DO NOT

paint the transducer. Performance

will be affected.

Hole for

stuffing tube

Saw along slope

of hull.

Upper Half

Lower Half

BOW

Flat Washer

Rubber Washer

Fairing

Block

Hull

Deep-V Hull

Hull

Flat Washer

Rubber

Washer

Cork

Washer

Flat Hull

Summary of Contents for FCV-627

Page 1: ...FISH FINDER FCV 627 OPERATOR S MANUAL www furuno com B R I L L GAIN ...

Page 62: ...D 1 ...

Page 63: ...D 2 ...