5-18

SPARC Enterprise T2000 Server Service Manual • April 2007

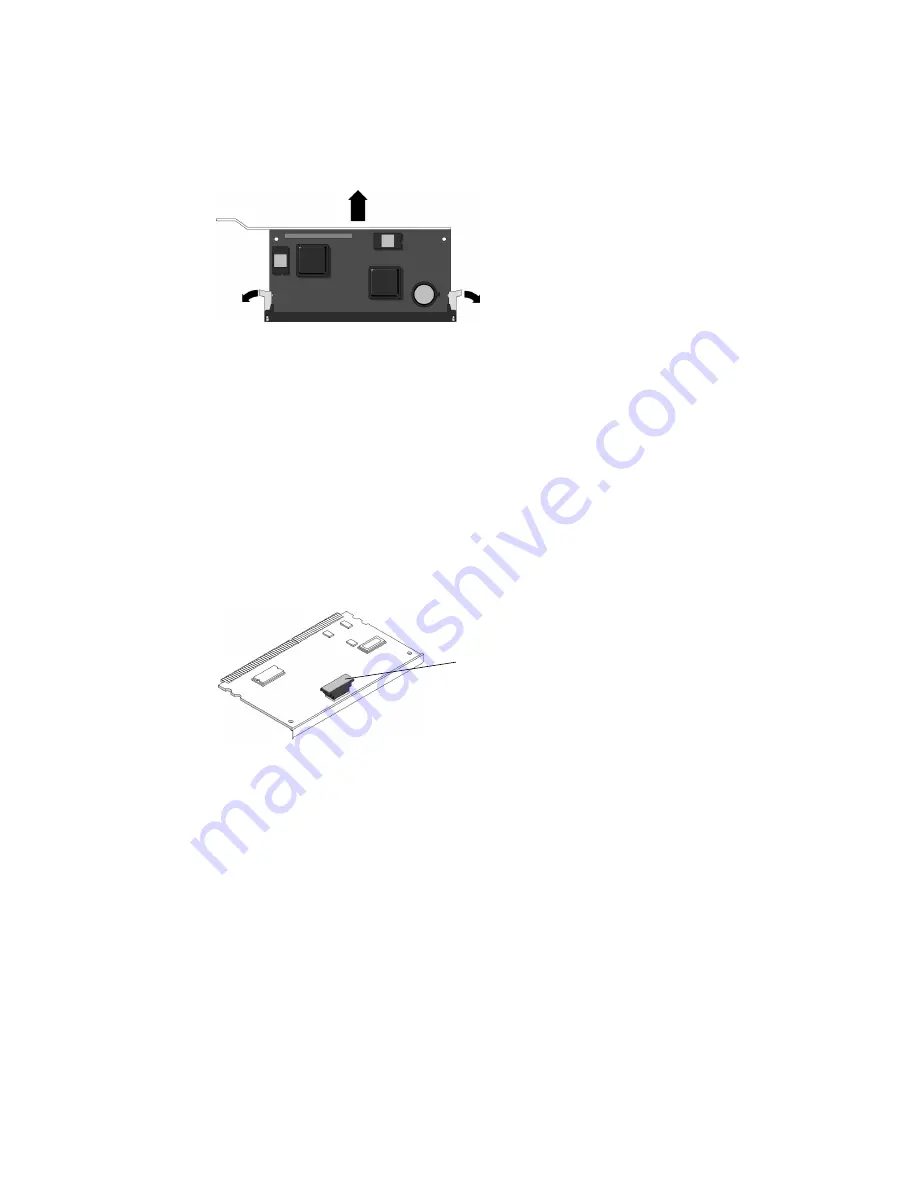

FIGURE 5-9

Ejecting and Removing the System Controller Card

4. Grasp the top corners of the card and pull it out of the socket.

5. Place the system controller card on an antistatic mat.

6. Remove the system configuration PROM (

) from the system controller

and place it on an antistatic mat.

The system controller contains the persistent storage for the host ID and Ethernet

MAC addresses of the system, as well as the ALOM CMT configuration including

the IP addresses and ALOM CMT user accounts, if configured. This information will

be lost unless the system configuration PROM is removed and installed in the

replacement system controller. The PROM does not hold the fault data, and this data

will no longer be accessible when the system controller is replaced.

FIGURE 5-10

Locating the System Configuration PROM

5.2.6

Replacing the System Controller Card

1. Unpackage the replacement system controller card and place it on an antistatic

mat.

2. Install the system configuration PROM that you removed from the faulty system

controller card.

The PROM is keyed to ensure proper orientation.

3. Locate the system controller slot on the motherboard assembly.

System configuration

PROM

Summary of Contents for SPARC Enterprise T2000

Page 1: ......

Page 2: ......

Page 6: ......

Page 16: ...xiv SPARC Enterprise T2000 Server Service Manual April 2007 ...

Page 18: ...xvi SPARC Enterprise T2000 Server Service Manual April 2007 ...

Page 27: ...Preface xxv Reader s Comment Form ...

Page 43: ...Chapter 3 Server Diagnostics 3 3 FIGURE 3 1 Diagnostic Flow Chart flowchart ...

Page 106: ...4 12 SPARC Enterprise T2000 Server Service Manual April 2007 ...

Page 152: ...5 46 SPARC Enterprise T2000 Server Service Manual April 2007 ...

Page 173: ......

Page 174: ......