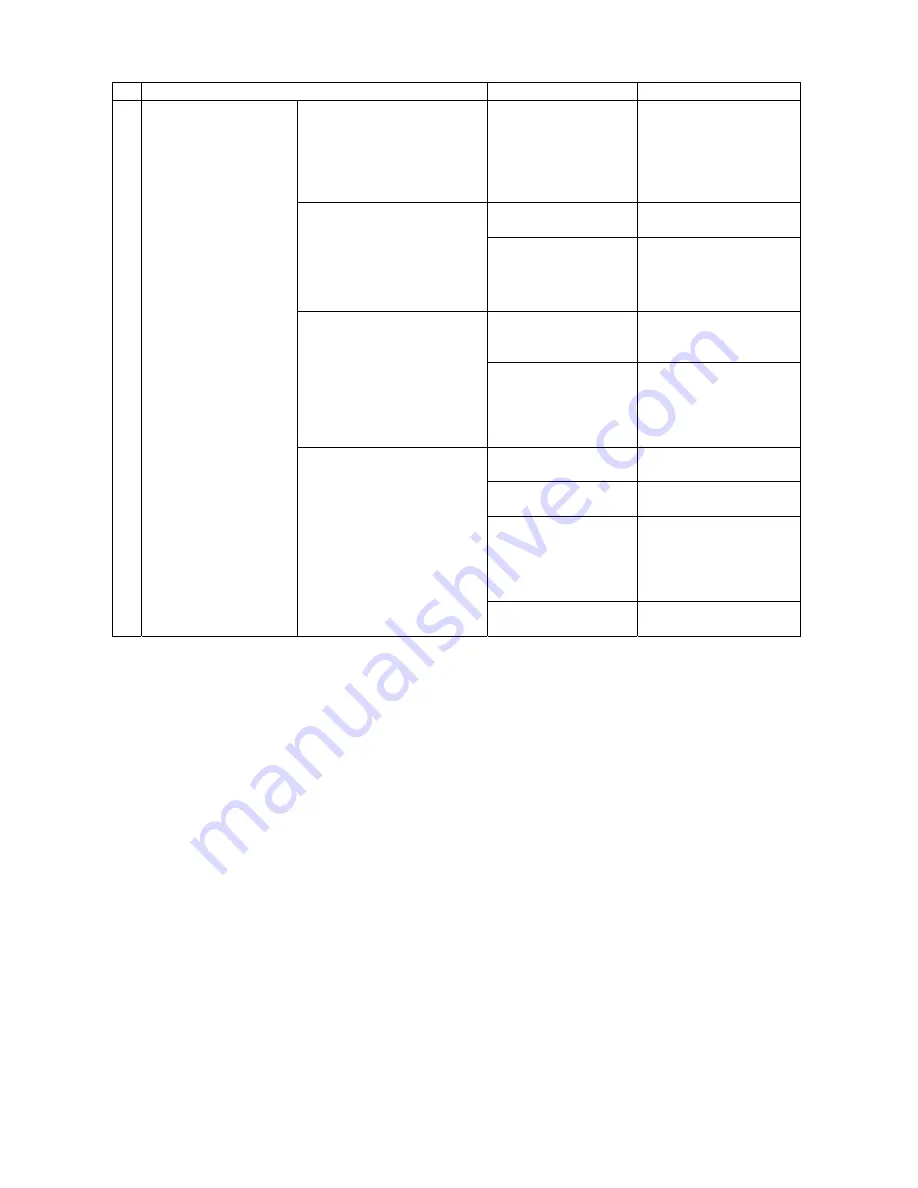

21

3.1.1 Problems at power-on initialization (part 002/3)

Symptom

Cause

Response

After the POWER lamp goes

on, simultaneous blinking of

all other lamps is not

performed.

The PAPER OUT lamp does

not blink, either.

The control board

is defective.

Replace and initialize

the control board.

The cover is open.

Close the front cover.

After the POWER lamp goes

on, simultaneous blinking of

all other lamps is performed

but initialization is not

performed normally.

The cover open switch

assembly is defective.

Replace the cover

open switch assembly.

The interface cable is

defective.

Replace the interface

cable.

After the POWER lamp goes

on, simultaneous blinking of

all other lamps is performed

but the PAPER OUT lamp

does not blink later. If the

interface cable is

disconnected, initialization is

performed normally.

The host is defective.

Check the host.

The control board is

defective.

Replace and initialize

the control board.

The control panel

board is defective.

Replace the control

panel board.

The cable

connected to the

control panel board is

defective.

Check the connection.

Replace the cable.

3 The POWER lamp is

on.

The case of as stated above.

Initialization is not

performed normally even if

the interface cable is

disconnected.

The cover is open.

Close the front cover.

Summary of Contents for Impact 3650

Page 112: ...112 ...