7-69

7.4 Test Mode Overview

7

O

P

E

R

AT

O

R

PA

N

E

L M

E

N

U

S

■

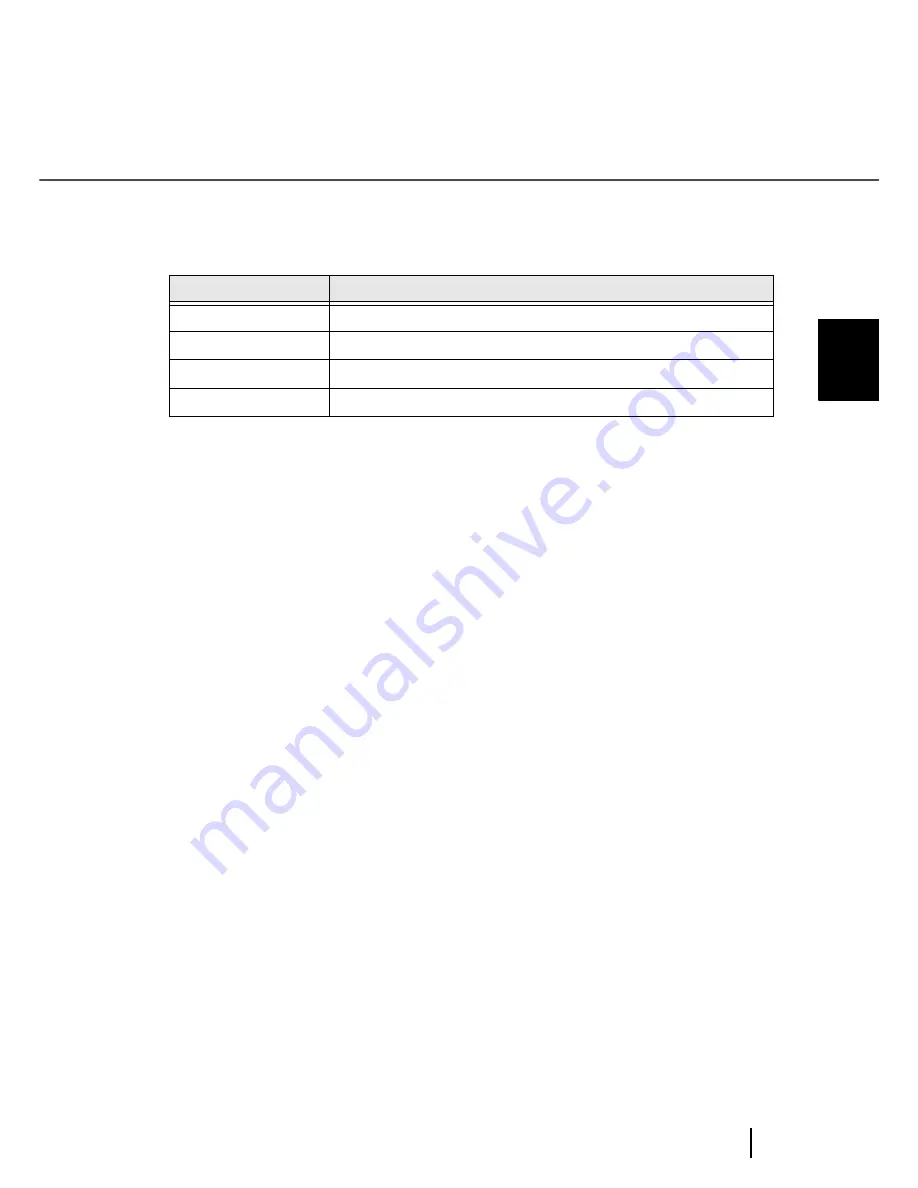

Contents of test mode setting

LCD display

Descriptions

Single feed

Scans a sheet of document without connecting to a PC.

Multi feed

Scans documents continuously without connecting to a PC.

Device Life

Shows the cumulative lamp-on time.

Options

Shows the options installation status.

Summary of Contents for fi-4860C

Page 1: ...Operator s Guide fi 4860C Image Scanner P3PC E167 04EN ...

Page 2: ......

Page 133: ...3 43 3 8 Cleaning the Lamps 3 DAILY CARE Glass sheet guide ...

Page 140: ...3 50 3 8 Cleaning the Lamps ...

Page 146: ...4 6 4 3 Replacing the Pad ASSY Pad cleaning area Pad ASSY Guide plate ...

Page 164: ...4 24 4 7 Replacing the Back side Lamp ...

Page 292: ...8 6 8 4 fi 486TRK Thinner paper Roller Kit ...

Page 297: ...9 5 9 3 Dimensions 9 3 Dimensions unit mm 20 5 in 20 6 in 17in 520 20 5 in 523 20 6 in ...

Page 298: ...9 6 9 3 Dimensions ...

Page 316: ... AP 18 ...

Page 320: ... IN 4 ...