4-2

006-240-20 2004.03

Utility Operation

4.1 What is Utility?

The DRYPIX 5000 offers Utility functions, which allow the users to operate processing such

as film count checking and automatic film density calibration, etc.

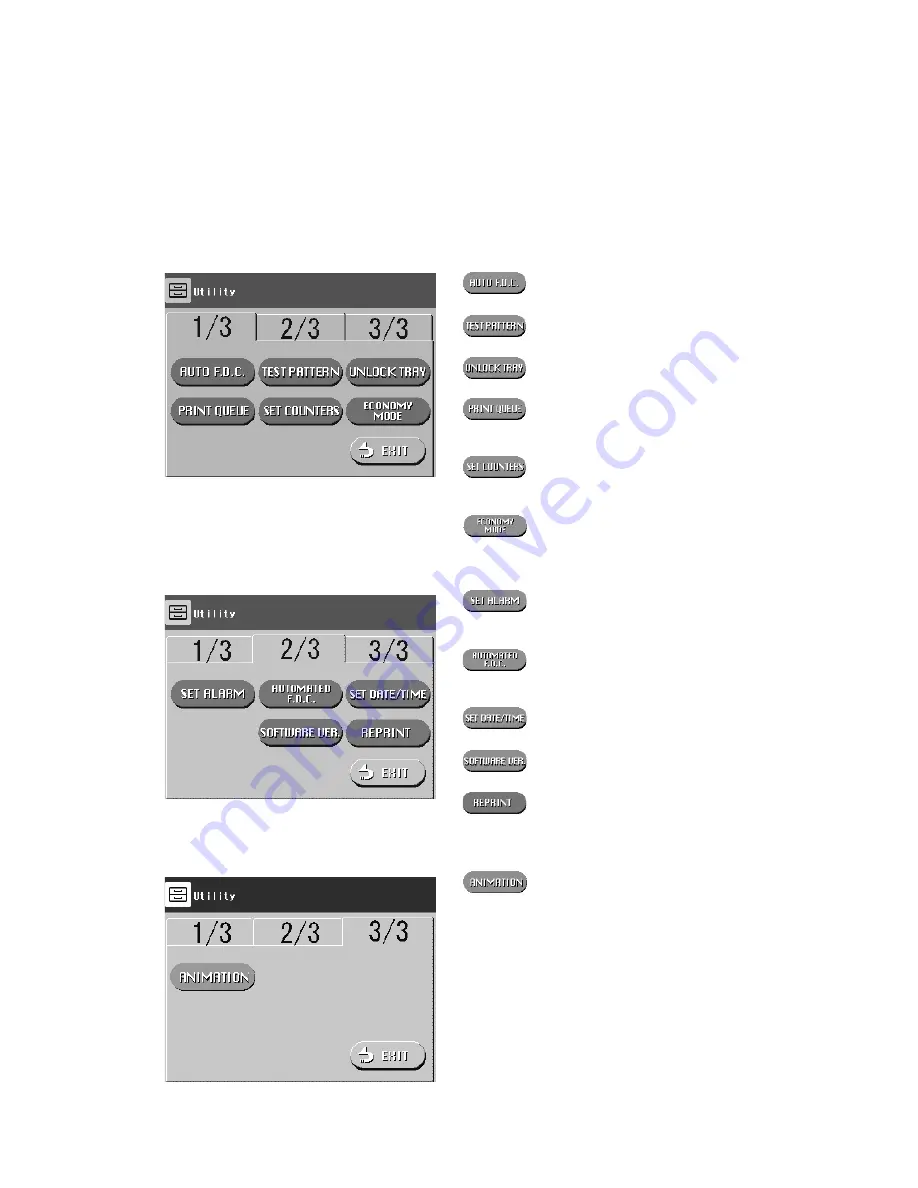

[ Fig. 4.1] Utility Initial Screen (1/3)

[ Fig. 4.1] Utility Initial Screen (2/3)

[ Fig. 4.1] Utility Initial Screen (3/3)

............................ See page

4-4

.

Calibrates the output film density automatically.

............................ See page

4-8

.

Outputs test pattern films.

............................ See page

4-12

.

Unlocks trays.

................................ See page

4-15

.

Deletes registered print jobs or handles

urgent print processing.

............................ See page

4-17

.

Displays the number of films used for each

tray and/or resets the film count.

............................ See page

4-20

.

Sets up power saving items.

............................ See page

4-45

.

Sets time interval for animation display.

............................ See page

4-35

.

Turns ON/OFF and adjusts the alarm or

button touch sound.

............................ See page

4-37

.

Sets the timing for performing automatic film

density calibration.

............................ See page

4-38

.

Adjusts the built-in clock.

............................ See page

4-40

.

Displays the software version.

............................ See page

4-41

.

Reprints images stored in the equipment.

Summary of Contents for Drypix 5000

Page 7: ...1 1 006 240 20 2004 03 1 Chapter 1 Introduction ...

Page 17: ...2 1 006 240 20 2004 03 2 Chapter 2 System Overview ...

Page 23: ...3 1 006 240 20 2004 03 3 Chapter 3 Basic Operation ...

Page 40: ...3 18 006 240 20 2004 03 Basic Operation ...

Page 41: ...4 1 006 240 20 2004 03 4 Chapter 4 Utility Operation ...

Page 87: ...5 1 006 240 20 2004 03 5 Chapter 5 Troubleshooting ...

Page 125: ...6 1 006 240 20 2004 03 6 Chapter 6 Regular Care and Maintenance ...

Page 130: ...6 6 006 240 60 2007 03 Regular Care and Maintenance ...

Page 131: ...7 1 006 240 20 2004 03 7 Chapter 7 Specifications ...

Page 136: ...7 6 006 240 20 2004 03 Specifications ...

Page 138: ...Maintenance and Inspection 006 240 20 2004 03 ...

Page 141: ......

Page 142: ...FUJIFILM MEDICAL SYSTEMS U S A INC 419 WEST AVENUE STAMFORD CT 06902 U S A ...