General Maintenance

FTS Systems LyoStar™ 3

58

Rev 006, 01/14

© SP Scientific 2014

Acrylic Parts

Clean acrylic parts with a mild detergent. Use a soft cloth or Kimwipes® to avoid

scratching the acrylic.

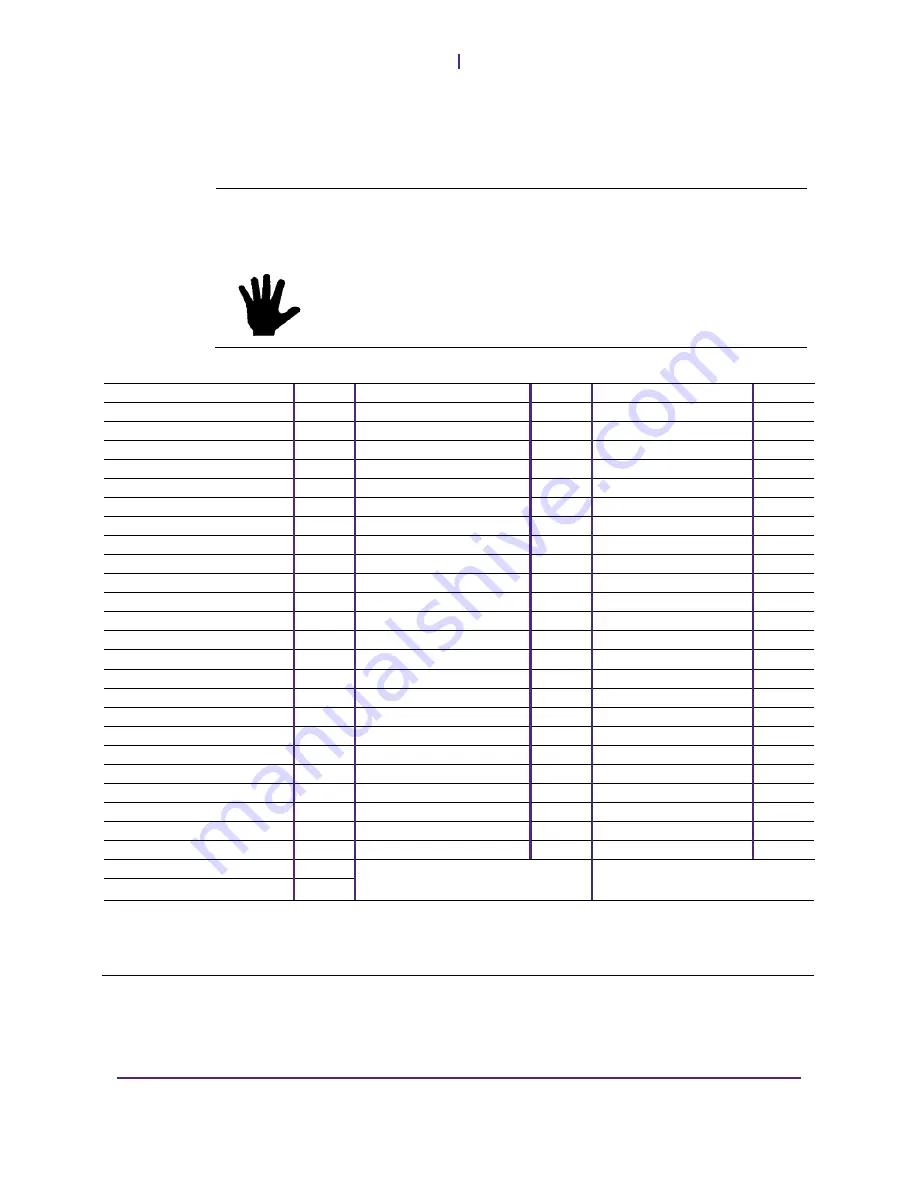

C

h

e

mical Resistance Chart

Chemical

Code

Chemical

Code

Chemical

Code

Acetic Acid (5%)

R

Ethyl Alcohol (50%)

LR

Nitric Acid (10%)

R

Acetic Acid (Glacial)

N

Ethyl Alcohol (95%)

N

Nitric Acid (40%)

LR

Acetic Anhydride

LR

Ethylene Dichloride

N

Nitric Acid (Conc.)

N

Acetone

N

Ethylene Glycol

R

Oleic Acid

R

Acetonitrile

N

2-Ethylhexyl Sebacate

R

Olive Oil

R

Ammonium Chloride (Saturated)

R

Formaldehyde (40%)

R

Phenol Solution (5%)

N

Ammonium Hydroxide (10%)

R

Gasoline (Regular, Leaded)

LR

Soap Solution (Ivory)

R

Ammonium Hydroxide (Conc.)

R

Glycerine

R

Sodium Carbonate (2%)

R

Aniline

N

Heptane

R

Sodium Carbonate (20%)

R

Battery Acid

R

Hexane (Commercial Grade)

R

Sodium Chloride (10%)

R

Benzene

N

Hydrochloric Acid

N

Sodium Hydroxide (1%)

R

Benzyl Alcohol

N

Hydrofluoric Acid (40%)

R

Sodium Hydroxide (10%)

R

Butyl Acetate

N

Hydrogen Peroxide (3%)

R

Sodium Hydroxide (60%)

R

Calcium Chloride (Sat.)

R

Hydrogen Peroxide (28%)

N

Sodium Hypochlorite (5%)

R

Calcium Hypochlorite

R

Isooctane

R

Sulfuric Acid (3%)

R

Carbon Tetrachloride

N

Isopropyl Alcohol

LR

Sulfuric Acid (30%)

R

Chloroform

N

Kerosene

R

Sulfuric Acid (Conc.)

N

Chromic Acid (40%)

N

Lacquer Thinner

N

Toluene

N

Citric Acid (10%)

R

Methyl Alcohol (50%)

LR

Transformer Oil

R

Cottonseed Oil (Edible)

R

Methyl Alcohol (100%)

N

Trichloroethylene

N

Detergent Solution (Heavy Duty)

R

Methyl Ethyl Ketone (MEK)

N

Turpentine

LR

Diesel Oil

R

Methylene Chloride

N

Water (Distilled)

R

Diethyl Ether

N

Mineral Oil

R

Xylene

N

Dimethyl Formamide

N

Naphtha (VM&P)

R

Trifluroacetic Acid

N

Dioctyl Phthalate

N

Ethyl Acetate

N

CODES

R = Resistant

(withstands long periods of exposure at temperatures up to 50 °C).

LR = Limited Resistance

(withstands short periods of exposure at room temperature).

N = Not Resistant

(immediate damage may occur upon exposure).

CAUTION! DO NOT USE ORGANIC SOLVENTS OR ABRASIVE CLEANERS.

Summary of Contents for LYOSTAR 3

Page 2: ......

Page 6: ...iv Rev 006 01 14 SP Scientific 2014...

Page 10: ...Contents FTS Systems LyoStar 3 viii Rev 006 01 14 SP Scientific 2014...

Page 18: ...Getting Started FTS Systems LyoStar 3 8 Rev 006 01 14 SP Scientific 2014...

Page 30: ...Operating your Lyophilizer FTS Systems LyoStar 3 20 Rev 006 01 14 SP Scientific 2014...

Page 36: ...Liquid Nitrogen Trap FTS Systems LyoStar 3 26 Rev 006 01 14 SP Scientific 2014...

Page 48: ...Sample Extractor Assemblies FTS Systems LyoStar 3 38 Rev 006 01 14 SP Scientific 2014...

Page 52: ...Stoppering FTS Systems LyoStar 3 42 Rev 006 01 14 SP Scientific 2014...

Page 56: ...Shelf Latching FTS Systems LyoStar 3 46 Rev 006 01 14 SP Scientific 2014...

Page 74: ...Appendix A Sample Recipe FTS Systems LyoStar 3 64 Rev 006 01 14 SP Scientific 2014...

Page 80: ...Appendix C Stainless Steel Cleaners FTS Systems LyoStar 3 70 Rev 006 01 14 SP Scientific 2014...

Page 81: ......