9

4) Clean the oil holes and bar

groove.

5) If the bar is burred, remove the

burs with a flat file.

6) If the rail top is uneven, use a flat

file to make the sides and edges

square again.

Replace the guide bar when the

groove is worn, the bar is bent or

cracked, or when excessive heating

or burring occurs. If the bar needs

replacing, only use the guide bar

specified in the parts list or on the

chain saw.

Oil passages

The oil passages should be cleaned

to allow proper lubrication of the bar

and chain.

The condition of the passages can

be checked. If they are clear, the

chain will automatically send off a

spray of oil within seconds of starting

the saw because it is equipped with

an automatic oiler system.

Automatic chain lubrication

The chain is equipped with an

automatic oil system with a toothed

wheel drive. It will automatically

supply the bar and chain with the

right amount of oil. When the engine

is accelerated, the oil will flow

through the bar more quickly.

The lubrication system has been set

at the factory. The screw for

adjusting the lubrication is located on

the underside of the chainsaw. By

turning the screw counterclockwise,

it will increase the lubrication and

turning it clockwise will decrease the

lubrication.

To check the lubrication, hold the

chain saw over a piece of paper and

run it at full speed for a few seconds.

The amount of oil on the paper will

determine if the lubrication needs to

be increased or not.

Chain Maintenance

Sharpening

Chain sharpening requires special

tools to ensure that the cutters are

sharpened to the proper angle and

depth. We recommend you allow a

professional chain sharpener to

sharpen your chain.

Breaking in a new chain

A new chain and bar will need

adjusting after as few as 5 cuts. This

is normal during the break-in period

and the interval between future

adjustments will begin to lengthen.

Chain lubrication

Make sure the oil tank is filled with

the appropriate oil to lubricate the

chain. Running the saw with low or

no oil will cause damage to the

chain and the saw, causing

overheating and excessive wear.

STORAGE

If a chainsaw is going to be in

storage for longer than 30 days,

follow these instructions.

Storing a chainsaw

1) Remove the fuel tank slowly in

order to release any pressure in the

tank. Carefully drain the fuel from

the tank.

2) To remove all of the fuel from the

carburetor, start the engine and let it

run until the saw stops.

3) Allow the engine to cool

completely.

4) Remove the spark plug.

5) Pour 1 teaspoon of 2-cycle oil into

the combustion chamber. Slowly pull

the starter rope a few times in order

to coat the internal parts. Replace

spark plug.

Note:

Store the unit away from

water, sources of flame and sparks

and in a cool, dry location.

Preparation to use saw again

1) Remove the spark plug.

2) Pull the starter rope briefly to

clear excess oil from the

combustion chamber.

3) Clean the spark plug and check

the electrode gap.

4) Replace the spark plug.

5) Fill the fuel tank with the proper

fuel mixture.

6) Check oil levels.

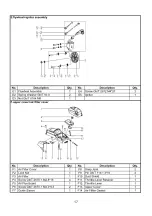

Summary of Contents for 20120

Page 13: ...13 Parts List...

Page 14: ...14...

Page 15: ...15...

Page 16: ...16...

Page 17: ...17...

Page 18: ...18...

Page 19: ...19...