6

Important Operation Reminders

Allow the engine to reach full speed

before cutting.

Begin cutting with the saw frame

resting against the log.

Keep the engine at full speed the

entire time you are cutting.

Allow the chain to do the work for

you. Do not apply excess pressure.

Forcing the cut may cause damage

to the engine, bar and/or chain.

When the cut is complete, release

the trigger and allow the engine to

return to idle. Running the saw at full

throttle without cutting can cause

wear to the chainsaw.

Do not put pressure on the saw at

the end of a cut in order to maintain

control of the saw.

Stop the engine before setting down

the saw.

Tree Felling

WARNING

: Do not cut near buildings

or electrical wires if the direction of

the fall is uncertain. Check for broken

or dead branches, which could fall

while cutting. Do not cut at night or

during bad weather. If the tree falls

onto a utility line, notify the utility

company immediately.

Plan your sawing operation in

advance. Clear the work area in

order to have a secure footing.

Evaluate the natural conditions that

could affect the direction of the fall

such as wind, lean of the tree, weight

and branches on one side,

surrounding trees, decay and rot.

Make sure the tree has enough room

to fall. Keep a distance of at least 2

½ tree lengths from the nearest

person or object because engine

noises or the tree falling can drown

out warning calls.

Remove all foreign objects from the

tree where the cuts are going to be

made. Plan a clear retreat path that

is diagonally back from the line

of the fall.

Felling Large Trees (6 in. or larger

in diameter)

A notch is cut into the side of the

tree in the desired falling direction.

After a felling cut is made, the tree

will tend to fall into the notch.

Note:

If the tree has large buttress

roots, remove them before making

the notch into the tree. If you use a

chainsaw to remove the roots, keep

the chain from contacting the ground

to prevent the chain from dulling.

1) Make the notch by cutting the top

of the notch first. Cut through 1/3 of

the diameter of the tree. Complete

the notch by cutting the bottom of

the notch. Remove the notch of

wood from the tree once the notch is

cut.

2) After removing the wood, make

the felling cut on the opposite side of

the notch. Make a cut about two

inches higher than the center of the

notch. This will leave a hinge

between the felling cut and the

notch. The hinge will help prevent

the tree from falling in the wrong

direction. It also helps hold the tree

on the stump and control the fall.

Before the felling cut is complete,

use wedges, if necessary, to open

the cut and control the direction of

the fall. Use wood or plastic wedges

to avoid kickback and chain

damage. Never use steel or iron

wedges.

Be alert to signs that the tree is

about to fall, such as cracking

sounds, widening of the felling cut,

or movement in the branches.

As the tree begins to fall, stop and

put down the saw and quickly get

away on your planned retreat path.

Do not cut down a partially fallen

tree. Be cautious when working

around partially fallen trees

because they may be poorly

supported. If a tree does not fall

completely, put the saw aside and

pull down the tree with a cable

winch, block and tackle or a tractor.

Cutting A Fallen Tree (Bucking)

WARNING:

DO NOT stand on the

log that is being cut. If the log rolls,

it can cause loss of footing and

control. Do not stand downhill of

the log being cut.

Only cut one log at a time.

Cut shattered wood carefully.

Sharp pieces of wood could

possibly be thrown back towards

the operator.

Never allow another person to hold

a small log for cutting, or use your

leg or foot to hold it. Use a

sawhorse to cut small logs.

Do not cut in an area where logs,

roots and limbs are tangled. Drag

the logs into a clear area before

cutting.

Types of Cutting for Bucking

WARNING: If a saw becomes

pinched in a log, do not try to force

it out. It is possible to lose control

of the saw which can result in injury

and/or damage to yourself or the

saw. Stop the saw and drive a

plastic or wood wedge into the cut

until the saw can be removed.

Restart the saw and re-enter the

cut. Using a metal wedge can

cause kickback and chain damage.

Do not attempt to restart your saw

when it is pinched in a log.

Summary of Contents for 20120

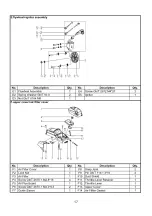

Page 13: ...13 Parts List...

Page 14: ...14...

Page 15: ...15...

Page 16: ...16...

Page 17: ...17...

Page 18: ...18...

Page 19: ...19...