8

Air Filter Cleaning

DO NOT clean the air filter in

gasoline or other flammable

solutions. Doing so can create a fire

hazard or harmful emissions.

DO NOT operate the saw without an

air filter. Dust and dirt will be drawn

directly into the engine and damage

it. Keep the air filter clean.

1) Remove the top cover by

unscrewing the fastening screw.

2) Lift out the air filter.

3) Clean the air filter in warm, soapy

water and rinse in clean water.

4) Allow the filter to air dry

completely.

5) Insert the air filter back into the

chainsaw. Replace the cover on the

chainsaw. Make sure the cover is

fitted securely and properly before

tightening the screw.

Fuel Filter Cleaning

NEVER use the saw without a fuel

filter. After 100 hours of use, the filter

should be cleaned or replaced, if

damaged.

Make sure the fuel tank is empty

before changing the filter.

1) Remove the fuel tank cap.

2) Bend a piece of soft wire.

3) Reach into the tank opening and

hook the fuel line. Carefully pull the

line towards the opening until you

can reach it with your fingers.

DO NOT pull the hose completely

out of the tank.

4) Lift the filter out of the tank.

5) Pull off the filter. If it is damaged,

discard and replace with a new one.

6) Insert a new filter. Place the filter

into the opening and push it into the

tank. Make sure it is situated in the

lower corner of the tank. If need be,

use a long screwdriver to

move the filter into the correct

position. Be careful not to damage the

filter.

7) Fill the tank with new fuel mixture.

Spark Plug

The spark plug must be cleaned or

replaced after every 20 hours of

service.

1) Make sure the ON/OFF switch is

turned off.

2) Remove the top cover by

unscrewing the fastener.

3) Remove the air filter.

4) Disconnect the ignition cable from

the spark plug by pulling and twisting

simultaneously.

5) Remove the spark plug by using a

spark plug wrench.

6) Clean the spark plug with a copper

wire brush. The electrode gap should

be 0.6mm.

7) Reconnect the ignition cable.

8) Replace the air filter.

9) Replace the top cover, make sure

the cover is securely fitted, and then

screw down the fastener.

Carburetor

The carburetor has already been

properly adjusted at the factory. If it

requires additional adjustment, take

the saw to an authorized service

dealer.

Chain Bar Maintenance

The chain bar needs to be regularly

lubricated and maintained in order for

it to work.

Tools for lubrication

A lube gun is recommended, but not

required, for applying grease to the

guide bar sprocket tip. The gun is

equipped with a needle nose tip,

which allows the grease to be

efficiently applied.

Lubricating the sprocket tip

The sprocket tip on your new saw

has been pre-lubricated in the

factory. It needs to be lubricated

properly otherwise it will perform

poorly, and possibly seize.

Lubrication is recommended once a

week or after 10 hours of use. Clean

the bar tip before lubrication.

The chain does not have to be

removed to lubricate the bar tip.

Lubrication is possible while

working, however the engine must

be turned off.

Warning:

Wear work gloves when

handling the chain and bar.

1) Make sure the engine is off, with

the ON/OFF switch in the Off

position.

2) Clean the guide bar tip.

3) Using the lubrication gun, insert

the nose into the lubrication hole and

fill it with grease until it appears at

the edges of the tip.

4) Rotate the saw by hand. Add

additional lubrication until the entire

tip has been greased.

Many guide bar problems can be

avoided by properly maintaining the

bar and chain saw. Insufficient

lubrication or using a saw with a

chain that is too tight will cause the

bar to wear rapidly.

Maintaining the chain bar

The bar should be reversed after 8

hours of work to keep uniform wear.

Check the bar frequently for wear,

and if need be, remove burs and

square up the rails by using the flat

file.

1) Be sure the ON/OFF switch is Off.

2) Loosen the bar knob and remove

the cover.

3) Remove the chain and bar from

the saw.

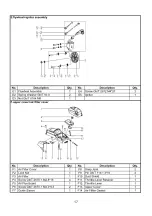

Summary of Contents for 20120

Page 13: ...13 Parts List...

Page 14: ...14...

Page 15: ...15...

Page 16: ...16...

Page 17: ...17...

Page 18: ...18...

Page 19: ...19...