5

6) Store the saw and fuel in an area

where sparks or open flame will not

reach it.

OPERATING INSTRUCTIONS

Warning: The chain must not move

when the engine is running at an idle

speed. If the chain moves, the

carburetor must be adjusted. Avoid

contact with the muffler because a

hot muffler can cause serious burns

or injury.

Operation Safety Instructions

1) Do not operate a chainsaw with

one hand.

2) Only operate the chainsaw in a

well-ventilated, outdoor area.

3) Make sure that the chainsaw will

not come into contact with any object

while starting the engine. Do not start

the saw when the guide bar is in the

4) Do not apply pressure to the saw

at the end of a cut. It can cause you

to lose control of the saw when the

cut is complete.

5) Make sure the engine is stopped

before setting down the saw.

6) Make sure your chainsaw is in

good condition before operating. Do

not operate a saw that is damaged,

improperly adjusted, or not

completely and securely assembled.

7) Do not carry the saw with the

engine running. Carry the saw with

the engine stopped and the muffler

pointing away from you, with the

guide bar and chain facing behind

you. The chain should be covered

with a bar cover to ensure the blade

will not cause harm.

8) Do not run while operating the

chainsaw.

Starting A Cold Engine

Hold the saw firmly against the

ground and make sure the chain is

free to move without contacting any

object.

1) Move the ON/OFF switch to the

ON position.

2) Pull the choke lever out to its full

extent.

3) Pull the starter rope quickly with

your right hand a maximum of 5

times. If the engine sounds as

though it is trying to start before the

5

th

pull, do not pull any more and

immediately go to the next step.

4) Push the choke lever fully in.

5) Pull the starter rope quickly with

your right hand until the engine

starts.

6) Allow the engine to run for

approximately 30 seconds before

squeezing and releasing the throttle

trigger, which will allow the engine to

return to idle speed.

Starting a Warm Engine

1) Place the ON/OFF switch into the

ON position.

2) Push the choke lever full in.

3) Pull on the starter rope quickly

with your right hand until the engine

starts.

4) After the engine starts, squeeze

and release the throttle trigger, this

will allow the engine to return to idle

speed.

Flooded Engine

If your engine does not start after 10

pulls, it may be flooded. It can be

cleared of the excess fuel by

following the warm engine starting

process. Make sure the

ON/OFF switch is in the ON position.

The amount of flooding in the engine

will determine how many pulls are

necessary for it to start.

Checking the Chain Brake

The chain brake should be checked

several times during use. The

engine needs to be running while

this is done and it is the only time

the saw should be set on the

ground with the engine running.

1) Place the saw on the ground.

2) Grasp the rear handle with your

right hand and the front with your

left.

3) Apply the full throttle with your

right hand.

4) Activate the chain brake by

turning your left wrist against the

hand guard without letting go of the

front handle.

The chain should stop immediately.

If the chain brake fails to activate,

take the saw to an authorized

dealer to have the chain brake

replaced or repaired.

CUTTING METHOD

INSTRUCTIONS

Safety Instructions

Check the chain tension before

using the saw for the first time and

after 1 minute of operation

Do not cut any material other than

wood. Do not cut metal, plastic,

masonry, non-wood building

materials, etc.

If the chain strikes a foreign object,

stop the saw and inspect the chain

for damage. If damage is present,

repair or replace the necessary

parts.

Keep the saw clear of dirt or sand

because even a small amount

could dull the blade and possibly

cause kickback.

Before starting a major project,

practice cutting a few logs.

middle of a cut.

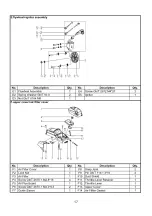

Summary of Contents for 20120

Page 13: ...13 Parts List...

Page 14: ...14...

Page 15: ...15...

Page 16: ...16...

Page 17: ...17...

Page 18: ...18...

Page 19: ...19...