33

Turn the frontlet so that one of the possible positions with the end of the screw is adjusted in one

line. Then screw on the srews clockwise so that they were guided through the particular holes

and adjust the hinge plates.

4.7 SELECTION OF COLOURING NUMBER The colouring number can be adjusted manually by

hand from 9 to 13. From the colouring table you will see the correct colouring number for the

personally selected application. Select the colouring by turning the knob as long as the arrow

shows the correct colour.

4.8 SELECTION OF DELAY TIME If welding is interrupted the view automatically changes from

dark to light but with a preset delay to dim the glaring light on the working piece from

reannealing. The delay or reaction time can be set as required, either 'fast' (0,25 up to 0,35 s) or

'slow' (0,6 up to 0,8 s) by applying the switch at the back of the cassette (see pict.3).

4.9 SENSITIVITY The sensitivity can be adjusted to ‘high’ or ‘low’ by applying the switch at the

back of the cassette. 'High' adjustment is the normal setting for daily use. If the usage of the

helmet is disturbed by too much light or by another welding device near the working place, the

setting shows ‘low’ (see pict.3).

4.10 Now the helmet is ready to start working. The colouring number can be adjusted during the

application due to turning at the knob.

5. MAINTENANCE

5.1 REPLACEMENT OF THE OUTSIDE SCREEN. Carefully insert finger or thumb into the

recess at the support for the protection screen and carefully fold the support upwards until the

screen comes out at one side. Press out the old protection screen out of the support. Remove

the protection film from the new protection screen and insert it at one side under a terminal strip

at the helmet. Now press onto the other side of the protection screen and let it snap in.

5.2 REPLACEMENT OT AUTOMATIC CASSETTE (see pict. 5a and 5b) Remove the colouring

adjustment knob and turn the nut from the threaded pin which projects sideways out of the

helmet. Let the potentiometer hang loosely at the cable. The cassette is held tightly from a metal

spring like shown in pict. 5b. Loosen the front side of the clamping spring (pict. 5a-D) by pulling

these out of the safety nose (pict. 5a-E) and turn the clamping spring upwards so that it is not

obstructive. Lift up the cassette with the potentiometer hanging at the cable out of the support.

5.3 INSTALLATION OF THE NEW AUTOMATIC CASSETTE Take the new cassette and make

sure that the cable of the potentiometer is under the clamping spring before you put the cassette

into the support inside the helmet. Turn the clamping spring downwards and fix it tightly und the

safety nose like shown in pict.5b.

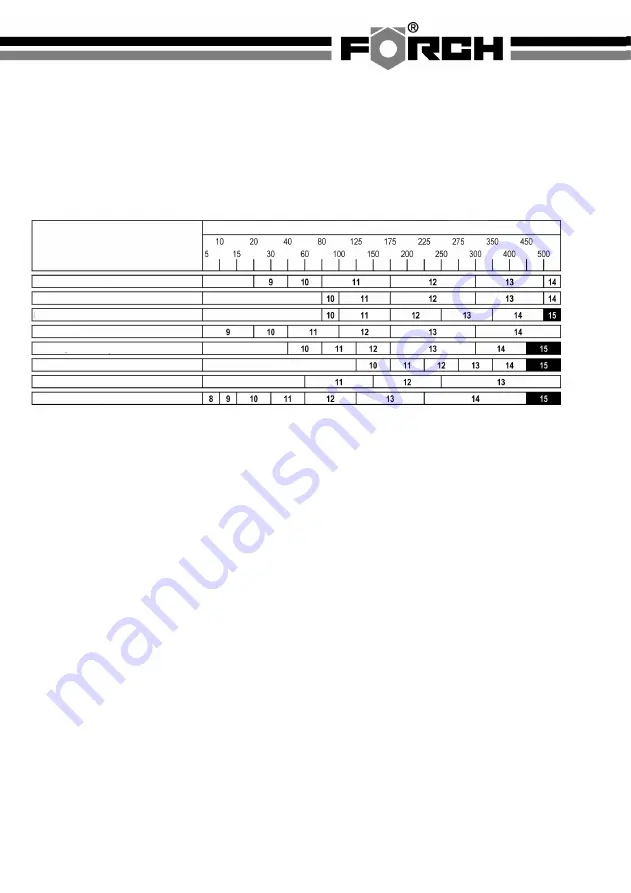

Colouring Table

ARC WELDING CURRENT (AMPERAGE)

Welding process

MIG

for heavy metals

MIG

for easy alloying

WIG,GTAW

Wolfram-Inert gas

MAG/CO2

metal active gas welding

SAW

semi automatic UP welding

PAC

plasma arc welding

PAW

plasma arc welding

SMAW

metal arc welding

Summary of Contents for 5400 400

Page 35: ...35...