Firepower MST 140i

Manual 0-5338

4-9

BASIC WELDING GUIDE

FAULT

CAUSE

REMEDY

7 Cold weld puddle

A Welding voltage too high

A Decrease voltage or increase the wirespeed

control.

B Loose welding cable connec-

tion

B Check all welding cable connections.

C Low primary voltage

C Contact supply authority.

D Fault in power source

D Have an Accredited Firepower Service Provider

to test then replace the faulty component.

8 Arc does not have a

crisp sound that short

arc exhibits when the

wirefeed speed and

voltage are adjusted

correctly.

The MIG Gun has been con-

nected to the wrong voltage

polarity on the front panel

Connect the MIG Gun to the positive (+)

welding terminal for solid wires and gas

shielded flux cored wires. Refer to the

electrode wire manufacturer for the correct

polarity.

9 Poor weld result from

setup chart param-

eters

A Incorrect welder setup, polar-

ity, shielding gas, wire type and

size

A Check to make sure that the welder is set up

correctly; also check polarity, shielding gas,

wire type and size.

B Contact tip has arc marks in the

bore causing excessive drag on

the wire

B Replace the contact tip with only a genuine

MST contact tip.

Table 4-4: MIG Welding Problems

4.03 Stick (SMAW) Basic Welding Technique

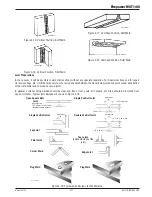

Size of Electrode

The electrode size is determined by the thickness of metals being joined and can also be governed by the type of welding

machine available. Small welding machines will only provide sufficient current (amperage) to run the smaller size electrodes.

For thin sections, it is necessary to use smaller electrodes otherwise the arc may burn holes through the job. A little practice

will soon establish the most suitable electrode for a given application.

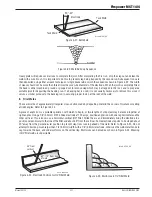

Storage of Electrodes

Always store electrodes in a dry place and in their original containers.

Electrode Polarity

Electrodes are generally connected to the ELECTRODE HOLDER with the Electrode Holder connected positive polarity. The

WORK LEAD is connected negative polarity and is connected to the work piece. If in doubt consult the electrode data sheet

or your nearest Accredited Firepower Distributor.

Summary of Contents for MST 140i

Page 6: ...This Page Intentionally Blank ...

Page 76: ...Firepower MST 140i BASIC WELDING GUIDE 4 24 Manual 0 5338 This Page Intentionally Blank ...

Page 82: ...Firepower MST 140i KEY SPARE PARTS 6 2 Manual 0 5338 6 02 Power Source Art A 12518 31 ...

Page 86: ...Firepower MST 140i KEY SPARE PARTS 6 6 Manual 0 5338 This Page Intentionally Blank ...

Page 87: ...Firepower MST 140i Manual 0 5338 1 APPENDIX APPENDIX This Page Intentionally Blank ...

Page 89: ...Firepower MST 140i Manual 0 5338 3 APPENDIX Art A 12517 ...