Firepower MST 140i

Manual 0-5338

4-13

BASIC WELDING GUIDE

Art # A-07699_AB

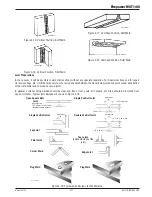

45° from

vertical

60° - 70° from line

of weld

Figure 4-23: Electrode Position for HV Fillet Weld

Art # A-07700_AB

1

2

3

4

5

6

Figure 4-24: Multi-runs in HV Fillet Weld

Art # A-07697_AB

Tack Weld

20°-30°

Electrode

Tack Weld

Figure 4-21: Butt Weld

Art # A-07698

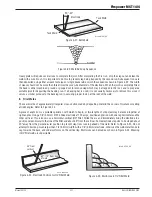

Figure 4-22: Weld Build up Sequence

Heavy plate will require several runs to complete the joint. After completing the first run, chip the slag out and clean the

weld with a wire brush. It is important to do this to prevent slag being trapped by the second run. Subsequent runs are

then deposited using either a weave technique or single beads laid down in the sequence shown in Figure 4-22. The width

of weave should not be more than three times the core wire diameter of the electrode. When the joint is completely filled,

the back is either machined, ground or gouged out to remove slag which may be trapped in the root, and to prepare a

suitable joint for depositing the backing run. If a backing bar is used, it is not usually necessary to remove this, since it

serves a similar purpose to the backing run in securing proper fusion at the root of the weld.

B. Fillet Welds

These are welds of approximately triangular cross-section made by depositing metal in the corner of two faces meeting

at right angles. Refer to Figure 4-14.

A piece of angle iron is a suitable specimen with which to begin, or two lengths of strip steel may be tacked together at

right angles. Using a 1/8"(3.2mm) E7014 Stick electrode at 100 amps, position angle iron with one leg horizontal and the

other vertical. This is known as a horizontal-vertical (HV) fillet. Strike the arc and immediately bring the electrode to a

position perpendicular to the line of the fillet and about 45º from the vertical. Some electrodes require to be sloped about

20º away from the perpendicular position to prevent slag from running ahead of the weld. Refer to Figure 4-23. Do not

attempt to build up much larger than 1/4"(6.4mm)width with a 1/8"(3.2mm) electrode, otherwise the weld metal tends to

sag towards the base, and undercut forms on the vertical leg. Multi-runs can be made as shown in Figure 4-24. Weaving

in HV fillet welds is undesirable.

Summary of Contents for MST 140i

Page 6: ...This Page Intentionally Blank ...

Page 76: ...Firepower MST 140i BASIC WELDING GUIDE 4 24 Manual 0 5338 This Page Intentionally Blank ...

Page 82: ...Firepower MST 140i KEY SPARE PARTS 6 2 Manual 0 5338 6 02 Power Source Art A 12518 31 ...

Page 86: ...Firepower MST 140i KEY SPARE PARTS 6 6 Manual 0 5338 This Page Intentionally Blank ...

Page 87: ...Firepower MST 140i Manual 0 5338 1 APPENDIX APPENDIX This Page Intentionally Blank ...

Page 89: ...Firepower MST 140i Manual 0 5338 3 APPENDIX Art A 12517 ...