Firepower MST 140i

BASIC WELDING GUIDE

4-20

Manual 0-5338

4.06 TIG (GTAW) Basic Welding Technique

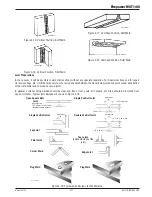

Gas Tungsten Arc Welding (GTAW) or TIG (Tungsten Inert Gas) as it is commonly referred to, is a welding process in which

fusion is produced by an electric arc that is established between a single tungsten (non-consumable) electrode and the work

piece. Shielding is obtained from a welding grade shielding gas or welding grade shielding gas mixture which is generally

Argon based. A filler metal may also be added manually in some circumstances depending on the welding application.

Welds Made With or Without

Addition of Filler Metal

Work Piece

Can Be Any Commercial

Metal

Gas Cup

Either Ceramic,

High Impact or

Water Cooled

Metal

Inert Gas

Shields Electrode

and Weld Puddle

Tungsten Electrode

Non-Consumable

Art # A-10369_AB

Figure 4-38: TIG Welding Application Shot

Tungsten Electrode Current Ranges

Electrode Diameter

DC Current (Amps)

0.040” (1.0mm)

30-60

1/16” (1.6mm)

60-115

3/32” (2.4mm)

100-165

1/8” (3.2mm)

135-200

5/32” (4.0mm)

190-280

3/16” (4.8mm)

250-340

Table 4-6: Current Ranges for Various Tungsten Electrode Sizes

Guide for Selecting Filler Wire Diameter

Filler Wire Diameter DC Current Range (Amps)

1/16” (1.6mm)

20-90

3/32” (2.4mm)

65-115

1/8” (3.2mm)

100-165

3/16” (4.8mm)

200-350

Table 4-7: Filler Wire Selection Guide

Summary of Contents for MST 140i

Page 6: ...This Page Intentionally Blank ...

Page 76: ...Firepower MST 140i BASIC WELDING GUIDE 4 24 Manual 0 5338 This Page Intentionally Blank ...

Page 82: ...Firepower MST 140i KEY SPARE PARTS 6 2 Manual 0 5338 6 02 Power Source Art A 12518 31 ...

Page 86: ...Firepower MST 140i KEY SPARE PARTS 6 6 Manual 0 5338 This Page Intentionally Blank ...

Page 87: ...Firepower MST 140i Manual 0 5338 1 APPENDIX APPENDIX This Page Intentionally Blank ...

Page 89: ...Firepower MST 140i Manual 0 5338 3 APPENDIX Art A 12517 ...