Firepower MST 140i

BASIC WELDING GUIDE

4-8

Manual 0-5338

Basic MIG Welding Troubleshooting

FAULT

CAUSE

REMEDY

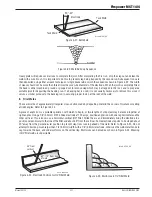

1 Undercut

A Welding arc voltage too high.

A Decrease voltage or increase the wire feed

speed.

B Incorrect MIG Gun angle

B Adjust angle.

C Excessive heat input

C Increase the MIG Gun travel speed and/or

decrease welding current by decreasing the

voltage or decreasing the wire feed speed.

2 Lack of penetration

A Welding current too low

A Increase welding current by increasing wire

feed speed and increasing voltage.

B Joint preparation too narrow or

gap too tight

B Increase joint angle or gap.

C Shielding gas incorrect

C Change to a gas which gives higher penetration.

3 Lack of fusion

Welding current too low

Increase welding current.

4 Excessive spatter

A Voltage too high

A Decrease voltage or increase the wirespeed

control.

B Voltage too low

B Increase the voltage or decrease wirespeed.

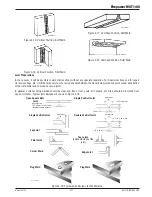

5 Irregular weld shape A Incorrect voltage and travel

speed settings. Convex, voltage

too low. Concave, voltage too

high.

A Adjust voltage and travel speed by adjusting the

voltage control and the wirespeed control.

B Wire is wandering.

B Check to see if it is near the end of the roll

of wire and replace when necessary. If the

problem continues, tighten the nozzle to see

if this corrects the problem. Then replace

contact tip.

C Incorrect shielding gas

C Check shielding gas.

D Insufficient or excessive heat

input

D Adjust the wirespeed control or the voltage

control.

E Incorrect gun manipulation or

angle

E Manipulate the gun correctly or place it in

correct angle.

6 Weld cracking

A Weld high carbon steel without

pre/post heat treatment

A Have sufficient pre/post heat treatment before

welding high carbon steel.

B Incompatible filler metal used

to the base metal

B Use correct filler metal.

C Weld beads too small

C Decrease travel speed.

D Weld penetration narrow and

deep

D Reduce current and voltage and increase MIG

Gun travel speed or select a lower penetration

shielding gas.

E Excessive weld stresses

E Increase weld metal strength or revise design

F Excessive voltage

F Decrease voltage.

G Cooling rate too fast

G Slow the cooling rate by preheating part to be

welded or cool slowly.

Summary of Contents for MST 140i

Page 6: ...This Page Intentionally Blank ...

Page 76: ...Firepower MST 140i BASIC WELDING GUIDE 4 24 Manual 0 5338 This Page Intentionally Blank ...

Page 82: ...Firepower MST 140i KEY SPARE PARTS 6 2 Manual 0 5338 6 02 Power Source Art A 12518 31 ...

Page 86: ...Firepower MST 140i KEY SPARE PARTS 6 6 Manual 0 5338 This Page Intentionally Blank ...

Page 87: ...Firepower MST 140i Manual 0 5338 1 APPENDIX APPENDIX This Page Intentionally Blank ...

Page 89: ...Firepower MST 140i Manual 0 5338 3 APPENDIX Art A 12517 ...