Summary of Contents for Mastersplit WP30

Page 40: ...MASTERSPLIT WP30 40 HYDRAULICS ...

Page 41: ...MASTERSPLIT WP30 41 ...

Page 44: ...MASTERSPLIT WP30 44 FRAME ...

Page 46: ...MASTERSPLIT WP30 46 TANK ...

Page 48: ...MASTERSPLIT WP30 48 CHAINSAW ...

Page 50: ...MASTERSPLIT WP30 50 CHAINSAW ...

Page 52: ...MASTERSPLIT WP30 52 WOOD SPLITTER ...

Page 54: ...MASTERSPLIT WP30 54 CONVEYOR ...

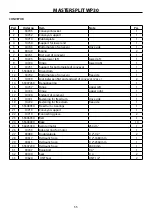

Page 56: ...MASTERSPLIT WP30 56 1 2 3 4 5 6 7 7 8 9 10 11 12 13 14 15 ELECTRIC ENGINE ...

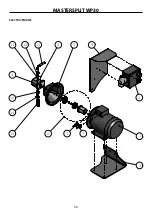

Page 58: ...MASTERSPLIT WP30 58 1 2 3 4 5 6 7 8 9 10 11 12 13 COMBUSTION ENGINE ...

Page 67: ......