4

TLP Pro 725C Series • Setup Guide (Continued)

Step 3 — Run all Cables

Run all cables necessary to support the AC connector, the cables stored in the cubby, and all planned AAP connectors. Run the

cables below the table and through the hole that was cut in

Step 2 — Cut the Surface

on the previous page. Leave enough slack

in the cables to connect or route them before the cubby is installed in the table. Leave enough space under the TLP Pro 725C

enclosure for the external power supply and connection of AV cables and the network connection.

Step 4 — Install Cable Retractors (Optional)

If required, Extron cable retractors must be purchased separately. It is difficult to mount the Cable Cubby into the table after the

retractors have already been installed so Extron recommends installing the empty retractor bracket at this point. The bracket

should be secured using the lowest level of mounting holes inside the touchpanel enclosure.

The retractors should be added to the bracket after

Step 8 — Mounting the Enclosure

on page 6. For complete information

about retractors and how to install them, see the

TLP Pro 725C User Guide

and

Retractors User Guide

at

www.extron.com

.

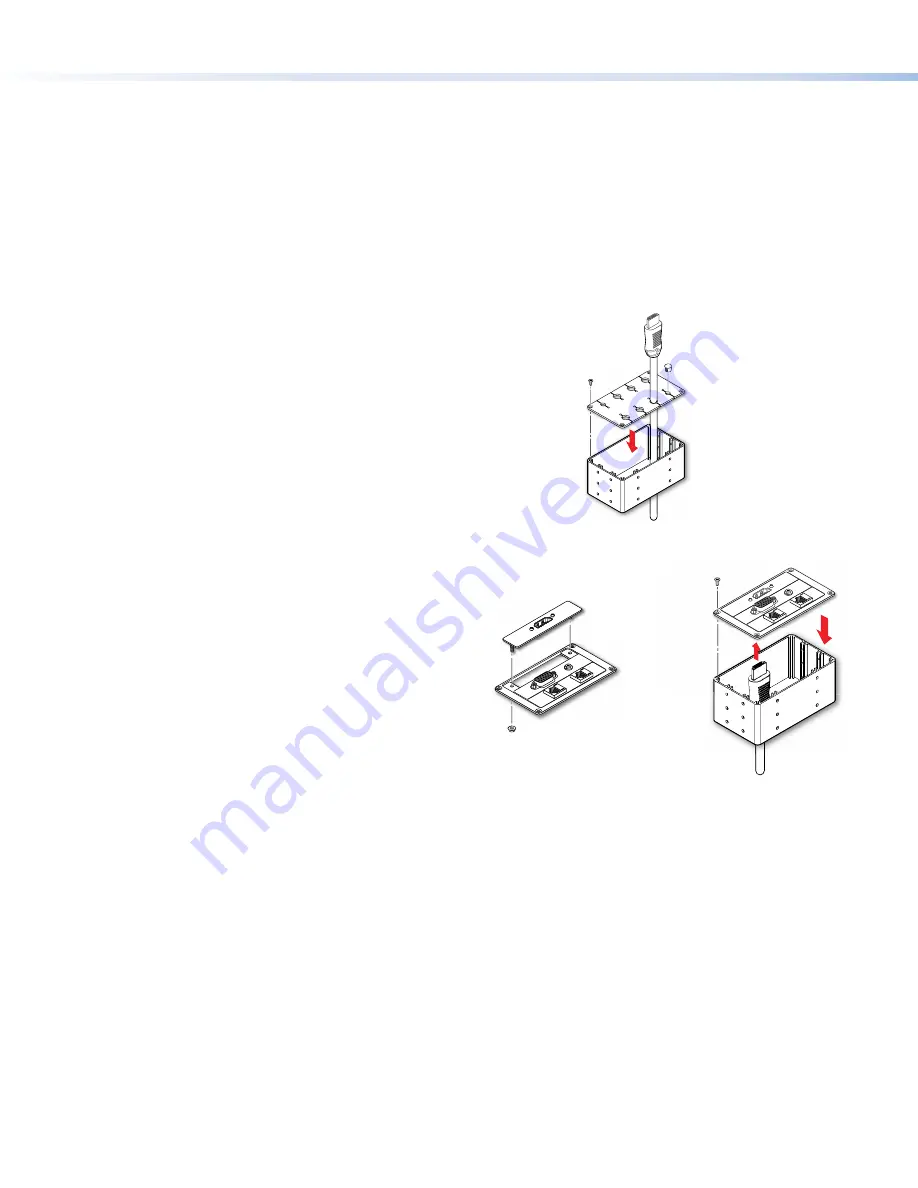

Step 5 — Assemble Pass-through Cable Module (Optional)

1.

Pass the cables through the connectivity module from the bottom (see

figure 5,

1

).

2.

Insert the cable into the grommet plate (

2

).

3.

Fill any unused holes with the provided plugs (

3

).

4.

Attach the grommet plate to the top of the connectivity module, using

four of the provided #4-40 thread forming screws (

4

).

To secure the pass-through cable module to the Touchpanel enclosure, see

Step 7 — Install Modules

on the next page.

3

2

1

4

Figure 5.

Installing pass-through cable module

Step 6 — Assemble AAP Module (Optional)

If required, AAPs must be purchased separately. Go to

www.extron.com

to see the full range of AAPs that are

available.

1.

Secure up to three single space AAPs in the AAP Frame,

using the #4-40 nut with captive washer provided with the

AAP (figure 6,

1

).

If required, fill any unused spaces with blank AAP plates.

2.

Insert cables through the bottom of the connectivity

module and connect them to the AAPs (

2

).

3.

Secure the AAP frame to the connectivity module, using

four of the provided #4-40 thread forming screws (

3

).

To secure the AAP module to the Touchpanel enclosure, see

Step 7 — Install Modules

on the next page.

3

2

#4-40 Nut with

Captive Washer

1

AAP

AAP Frame

Connectivity

Module

3

3

3

3

Figure 6.

Assemble the AAP Module