3

Product Category

Step 1 — Cut-out Dimensions

ATTENTION:

•

The opening in the table for the Cable Cubby should be cut only by licensed and bonded craftspeople. Exercise care to

prevent scarring or damaging the furniture.

•

L’ouverture dans la table pour le Cable Cubby doit être coupée uniquement par un ouvrier détenteur d’une licence. Veillez

à ne pas laisser de marques ni à détériorer le mobilier.

•

Use the appropriate metal Extron routing template or refer to the surface cutout dimensions before cutting a hole in the

furniture or other surface. Pay special attention to the direction the unit will face. The connector access side is underlined

(see Using a CNC wood cutter below). Extron is not responsible for miscut mounting holes.

•

Utilisez le gabarit de détourage métallique approprié ou reportez-vous aux dimensions de découpe de la surface

indiquées ci-après avant de découper le meuble ou la surface. Faites particulièrement attention à la direction dans

laquelle l’unité sera dirigée. Le côté pour accéder au connecteur est souligné. Extron décline toute responsabilité en cas

d’erreurs de coupe.

•

Ensure that the orientation of the Cable Cubby and the hole dimensions are correct before cutting the table.

•

Assurez vous que la position du Cable Cubby et les dimensions du trou soient correctes avant de couper la table.

•

Ensure the table surface is at least 0.375 inch (9.5 mm) thick.

•

Assurez vous que la surface de la table est au moins 9,5 mm (0,375 pouce) d’épaisseur.

If using a hand router, you should purchase the Extron TLP Pro 725C routing template (see “Installation Routing Templates for

Cable Cubby Series/2 Enclosures” at

www.extron.com

).

If using a CNC wood router, use the exact cut-out dimensions (see Using a CNC wood cutter below).

If using a reciprocating saw or jigsaw, use the paper cut-out template (available under the Downloads tab on the TLP Pro 725C

page at

www.extron.com

).

Step 2 — Cut the Surface

CAUTION:

Risk of personal injury: Wear safety glasses when operating power equipment.

ATTENTION :

Risque de blessure: Portez des lunettes de sécurité lorsque vous utilisez l’équipement électrique.

Be certain the cut is laid out in exactly the desired location and the edge that opens on the lid is correctly oriented. After verifying

and checking dimensions, cut a hole in the surface of the furniture where the enclosure will be installed (see “Preparing the Table”

in the

TLP Pro 725C Series User Guide

). There are three methods for cutting the hole in the table:

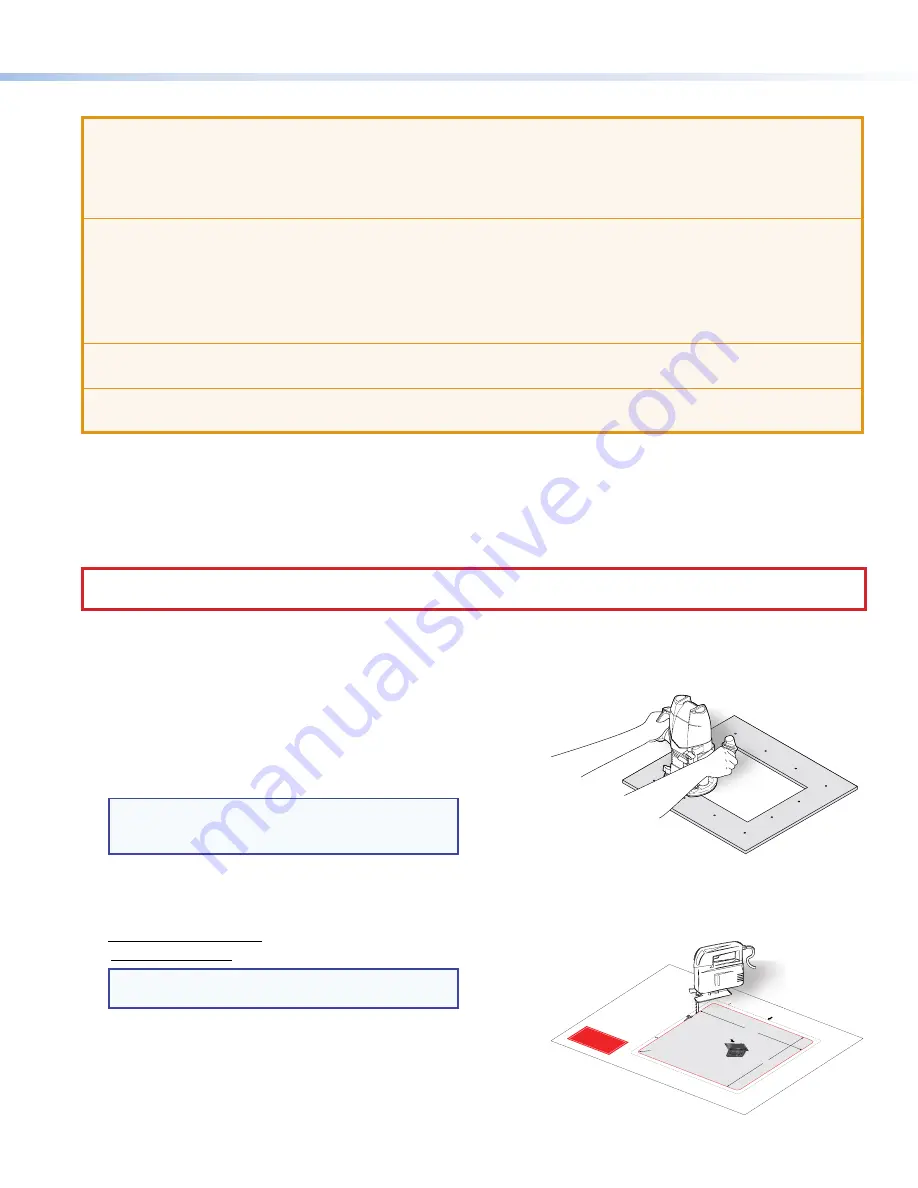

Using a hand router

Recommended method

— Use the Extron TLP Pro 725C

routing template (see “Installation Routing Templates for

Cable Cubby Series/2 Enclosures” at

www.extron.com

).

Refer to the

Routing Template User Guide

, available at

www.extron.com

, to prepare the template and use the

template to cut the hole.

NOTE:

The metal routing template must be

purchased separately. It is reusable and should not

be discarded when the installation is complete.

Using a CNC wood cutter

Recommended method

— Use the exact cut-out

dimensions:

8.90 +0.00/-0.02 inches W x 7.10 +0.00/-0.02 inches D

(226 +0.0/-0.1 mm W x 180 +0.00/-0.1 mm D)

NOTE:

The underlined dimension is the connector or

AAP access side for the unit.

Using a reciprocating saw or jigsaw

Acceptable method

— Use the paper cut-out template

(available under the

Downloads

tab on the TLP Pro 725C

product page at

www.extron.com

).

USE

R AC

CES

S

EXTR

ON E

LEC

TRO

NICS

TLP 7

10C

V RO

UTE

R GU

IDE -

ALL

MO

DELS

STAN

DAR

D

0.625

IN O

UTS

IDE D

IAM

ETER

GUID

E BU

SHIN

G

0.500

IN C

UT D

IAM

ETER

STR

AIGH

T RO

UTE

R BIT

MET

RIC

16 M

M O

UTS

IDE D

IAM

ETER

GUID

E BU

SHIN

G

12 M

M O

R 12

.7 M

M C

UT D

IAM

ETER

STR

AIGH

T RO

UTE

R BIT

AND

A

Figure 3.

Using a hand router

Cut-

Out

Tem

pla

te fo

r th

e Ex

tron

TLP

Pro

720

C and

TLP

Pro

725

C

1.

Con

firm

th

e pr

odu

ct t

o be

ins

tal

led.

2.

Dou

ble

-ch

eck

th

e pr

int

se

ttings

,

befo

re

ing

, a

nd

mak

e s

ure

the

pa

ge

is

not

sc

ale

d.

3.

R

em

ove

th

e su

rfa

ce

cut-out

are

a

(gr

ay)

fr

om

the

te

mpl

ate

by

cut

tin

g

along

the

re

d li

ne.

DO

N

OT CU

T th

e gr

ay

dot

ted

line

s.

4.

Mea

sure

the

cu

tou

t a

nd te

mpl

ate

.

Mak

e sure

th

e di

mens

ion

s a

re th

e

sam

e a

s thos

e sh

own

.

5.

Pla

ce

the

te

mpl

ate

and

mar

k th

e

pos

ition

on

the

m

oun

ting

su

rfa

ce

whe

re

the

R

WM

2

is

bein

g in

sta

lle

d.

6.

D

oub

le

che

ck

pos

itio

n an

d

dim

ens

ion

s, t

hen

cut

th

e o

peni

ng

in th

e wa

ll.

68-21

79-

02 R

ev.

B

Trim

Ri

ng

Oute

r E

dge

(Do

not

cu

t th

is lin

e.)

Page

si

ze:

11"

x 17

"

Prin

t sc

ale

1:1

Do n

ot s

hrink

.

User

Acces

s

User

A

cce

ss

R =

0.

25"

(6

.4

mm

)

7.1

0"

(18

0 m

m)

8.9

0"

(22

6 m

m)

+ 0

.00

" (0

.00

cm

)

- 0

.02

" (0

.05

cm

)

SU

RFA

CE

CUT

-OU

T

ARE

A

Trim

R

ing

Lip

Widt

h =

0.

325

" (8

.3

mm

)

Trim

R

ing

O

Trim

r E

dge

r E

dg

er E

d

ter E

d

ute

rE

(Do

not

cu

t

(Do

his

line

.

his

l

his

li

this

li

this

l

th

is

)

Figure 4.

Using a reciprocating saw or jigsaw