Maintenance

screw clockwise or counterclockwise to adjust the

travel of the lever.

Figure 72

1.

Access hole on front

cover panel

2.

Tracking screw

2. Drive the machine and check the full forward

tracking.

3. Repeat steps 1 and 2 until desired tracking is

obtained.

Motion Control Linkage

Adjustment

Located on either side of the unit, below the seat are

the pump control linkages. Rotating the end nut with

a 1/2 inch deep socket wrench allows fine tuning

adjustments so that the machine does not move in

neutral. Any adjustments should be made for neutral

positioning only.

WARNING

Engine must be running and drive wheels must

be turning so adjustments can be performed.

Contact with moving parts or hot surfaces may

cause personal injury.

Keep fingers, hands, and clothing clear of

rotating components and hot surfaces.

1. Prior to starting the engine, push the deck lift

pedal and remove the height of cut pin. Lower

deck to the ground.

2. Raise the rear of machine up and support with

jack stands (or equivalent support) just high

enough to allow drive wheels to turn freely.

3. Remove the electrical connection from the seat

safety switch, located under the bottom cushion

of the seat. The switch is a part of the seat

assembly.

4.

Temporarily

install a jumper wire across the

terminals in the connector of the main wiring

harness.

5. Start engine.

Brake must be engaged and

motion control levers out to start engine.

Operator does not have to be in the seat.

Run

engine at full throttle and release brake.

6. Run the unit at least 5 minutes with the drive

levers at full forward speed to bring hydraulic oil

up to operating temperature.

Note:

The motion control lever needs to be in

neutral while making any necessary adjustments.

7. Bring the motion control levers into the neutral

position. The control plate tabs should touch the

return to neutral plates on the hydros. Adjust

pump control rod lengths by turning the nut in

the appropriate direction until the wheels slightly

creep in reverse (see Figure 73). Move the motion

control levers to the reverse position and while

applying slight pressure to the lever allow the

reverse indicator springs to bring the levers back

to neutral. The wheels must stop turning or

slightly creep in reverse.

The motion control cover may need to be

removed to gain access.

67

Summary of Contents for RADIUS

Page 1: ...RADIUS For Serial Nos 400 000 000 Higher Part No 4502 907 Rev B ...

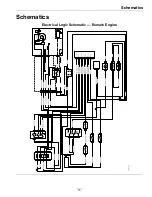

Page 73: ...Schematics Schematics Electrical Logic Schematic Exmark Engine 73 ...

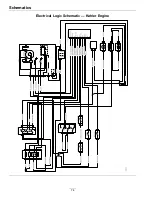

Page 74: ...Schematics Electrical Logic Schematic Kohler Engine 74 ...

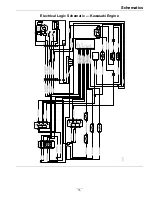

Page 75: ...Schematics Electrical Logic Schematic Kawasaki Engine 75 ...

Page 79: ...Notes 79 ...

Page 80: ...Notes 80 ...

Page 81: ...Service Record Date Description of Work Done Service Done By 81 ...

Page 82: ...82 ...