Maintenance

Check Rollover Protections

Systems (Roll Bar) Knobs

Service Interval: Before each use or daily

Check that both the mounting hardware and the

knobs are in good working condition. Make sure the

knobs are fully engaged with the ROPS in the raised

position. The upper hoop of the roll bar may need

to be pushed forward or pulled rearward to get both

knobs fully engaged.

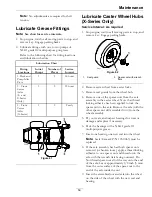

Figure 59

1.

Engaged

2.

Partially engaged — Do

Not operate with ROPS

in this condition.

Check Seat Belt

Service Interval: Before each use or daily

Visually inspect seat belt for wear, cuts, and proper

operation of retractor and buckle. Replace before

operating if damaged.

Check for Loose Hardware

Service Interval: Before each use or daily

1. Stop engine, wait for all moving parts to stop, and

remove key. Engage parking brake.

2. Visually inspect machine for any loose hardware

or any other possible problem. Tighten hardware

or correct the problem before operating.

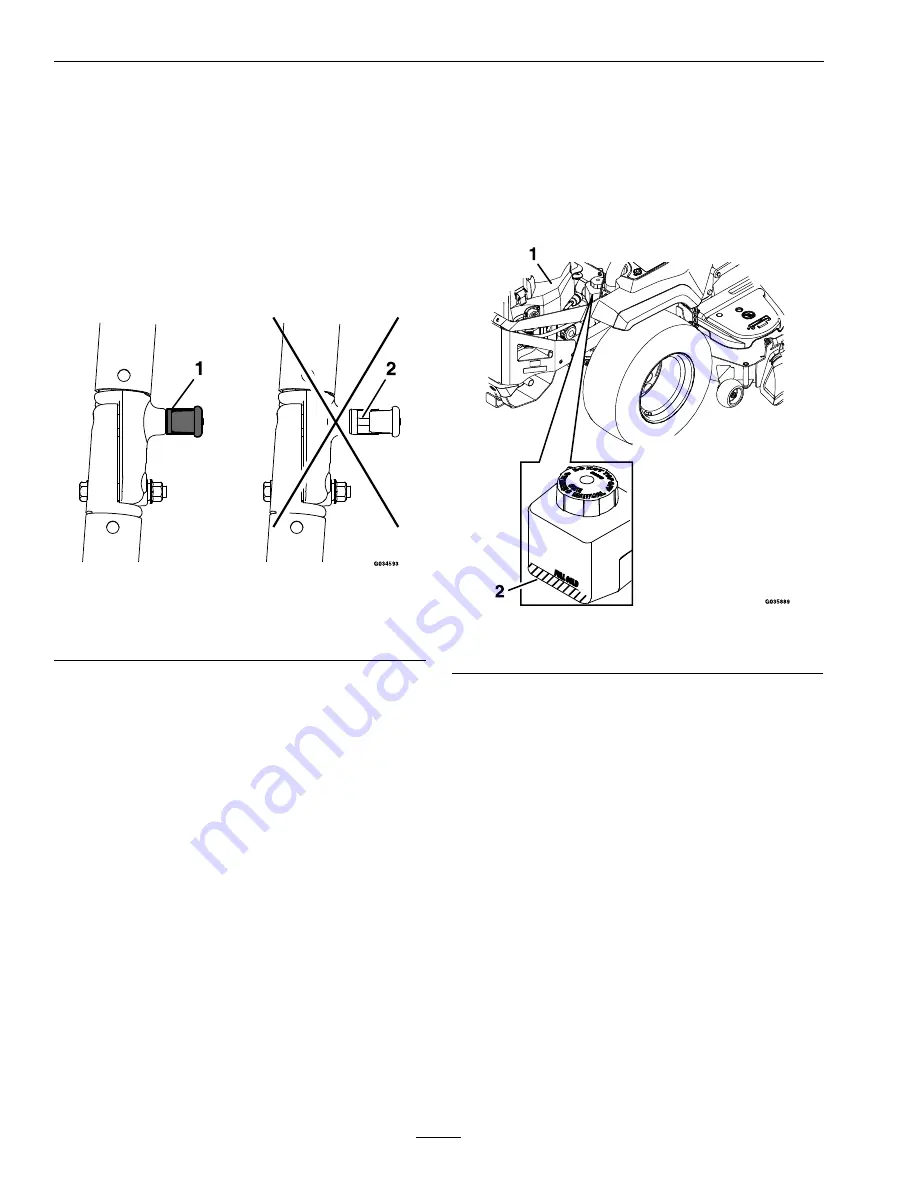

Check Hydraulic Oil Level

Service Interval: Before each use or daily

1. Stop engine and wait for all moving parts to stop.

Engage parking brake.

2. Wait until the unit cools before checking the

hydraulic oil.

3. Check expansion tank and if necessary add

Exmark Premium Hydro Oil to the FULL COLD

line (see Figure 60).

Figure 60

1.

Engine

2.

Expansion tank

Check Tire Pressures

Service Interval: Every 50 hours

1. Stop engine, wait for all moving parts to stop, and

remove key. Engage parking brake.

2. Check tire pressure in drive tires.

3. Inflate drive tires to 13 psi (90 kPa).

4. Check tire pressure in caster tires.

5. Inflate caster tires to 13 psi (90 kPa).

Check Condition Of Belts

Service Interval: Every 50 hours

1. Stop engine, wait for all moving parts to stop, and

remove key. Engage parking brake.

2. Remove left and right belt shields on deck and

lower the deck to inspect deck drive belt.

3. Check under machine to inspect the pump drive

belt.

58

Summary of Contents for RADIUS

Page 1: ...RADIUS For Serial Nos 400 000 000 Higher Part No 4502 907 Rev B ...

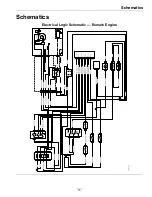

Page 73: ...Schematics Schematics Electrical Logic Schematic Exmark Engine 73 ...

Page 74: ...Schematics Electrical Logic Schematic Kohler Engine 74 ...

Page 75: ...Schematics Electrical Logic Schematic Kawasaki Engine 75 ...

Page 79: ...Notes 79 ...

Page 80: ...Notes 80 ...

Page 81: ...Service Record Date Description of Work Done Service Done By 81 ...

Page 82: ...82 ...