www.evolutionfury.com

8

22. Never stand on this tool.

Serious

injuries could occur if this tool tips over and

you come into contact with the saw blade.

23. Reduce the risk of unintentional

starting.

Make sure switch is in off position

before plugging in.

25. Do not use the saw without the guards

in position, especially after a mode change,

and to keep guards in good working order

and properly maintained.

26. The Riving Knife shall not be thicker

than the width of the groove cut by the

saw blade and not thinner than the body

of the blade.

27. Ensure that the arm is securely fixed

when beveling.

28. Always put the push stick into

storage when not in use.

29. Keep the floor area free of loose

material e.g. chips and off cuts.

30. Ensure that the bench saw table is

securely fixed at the chosen height.

31. Ensure that the speed marked on the

saw blade is at least equal to the speed

marked on the saw.

32. Ensure that the upper portion of the

saw blade is completely enclosed in mitre

saw mode.

33. Refrain from removing any off cuts

or other parts of the workpiece from

the cutting area whilst the machine is

running and the saw head is not in the

rest position.

34. The saw shall not be used for slotting

(stopped groove).

35. Always clamp the workpiece to the

saw table in mitre saw mode.

Ensure

before each cut that the machine is stable.

WARNING:

The operation of any table mitre

saw can result in foreign objects being

thrown into your eyes, which can result in

severe eye damage. Before beginning power

tool operation, always wear safety goggles

or safety glasses with side shield and a full

face shield when needed.

WARNING:

If any parts are missing, do not

operate your table mitre saw until the missing

parts are replaced. Failure to follow this rule

could result in serious personal injury.

ADDITIONAL SAFETY ADVICE

CARRYING YOUR TABLE MITRE SAW

Safety Advice

1. Although compact, this saw is heavy. To

reduce the risk of back injury, get competent

help whenever you have to lift the saw.

2. To reduce the risk of back injury, hold the

tool close to your body when lifting. Bending

your knees so you can lift with your legs, not

your back. Lift by using the handhold areas

at each side of the machines base.

3. Never carry the Table Mitre Saw by the

power cord. Carrying the tool by the power

cord could cause damage to the insulation

or the wire connections resulting in electric

shock or fire.

4. Before moving the saw tighten the mitre

and bevel locking screws to guard against

sudden unexpected movement.

5. Lock the Cutting Head in its lowest position.

Ensure that the Cutting Head Locking Pin is

completely engaged in its socket.

WARNING:

Do not use the blade guard as

a ‘lifting point’. The power cord must be

removed from the power supply before

attempting to move the machine.

•

Lock the Cutting Head in the down

position using the Cutting Head locking

pin.

•

Loosen the Mitre Angle Locking Screw.

Turn the table to either of its maximum

settings.

•

Lock the table in position using the

Locking Screw.

•

Use the two carry handle cut-outs

machined into either side of the

machine base, to transport the

machine.

Place the saw on a secure stationary

work surface and check the saw over

carefully.

Check particularly the operation of all the

machines safety features before attempting

to operate the machine.

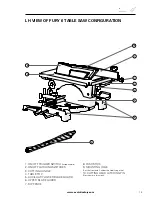

Summary of Contents for Fury 6

Page 2: ...www evolutionfury com 2 03 GB...

Page 29: ...www evolutionfury com 29...

Page 30: ...www evolutionfury com 30...

Page 31: ...www evolutionfury com 31...