www.evolutionfury.com

20

NOTE:

Always make a ‘dry run’ with the

machine switched ‘off’ so that the path of

the blade can be checked. Some Bevel and

Compound Cuts may require the Hold Down

Clamp to be positioned to the RH side of the

Cutting Head. This may be necessary to avoid

interference with the blade and other parts of

the machine as the Cutting Head is lowered.

8. Fence Adjustment

NOTE:

The left hand side of the fence is

provided with additional adjustments. The

upper portion of the fence can slide to the

left to provide clearance for the blade. This

may be necessary when acute bevel angles

are selected.

To adjust the fence:

• Loosen the thumbscrew.

(Fig 14)

• Slide the upper portion of the fence to

the required position and tighten the

thumbscrew.

• Lower the Cutting Head to check the path

of the blade. Ensure there is no interference

with any other parts of the machine.

9. Compound Cutting

A Compound Cut is a combination of a Mitre

Cut and Bevel Cut.

• Set the Mitre Angle required as previously

described.

• Set the Bevel Angle as previously described.

• Ensure the tightness of all adjustment/

locking screws, and conduct a ‘dry run’ to

check the path of the blade.

• Make the cut as previously described.

10. Cutting Bowed Material (Fig 15)

Before cutting any workpiece, check to see

if it is bowed. If it is bowed the workpiece

must be positioned and cut as shown. Do not

position the workpiece incorrectly or cut the

workpiece without the support of the fence.

11. Clearing Jammed Material

• Turn mitre saw “OFF” .and allow the

blade to come to a complete halt.

• If possible allow the Cutting Head to rise

to its upper position.

• Unplug the Mitre Saw from the mains

supply.

• Carefully remove any jammed material

from the machine.

Fig. 15

Fig. 14

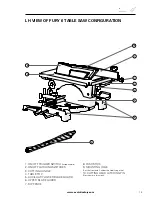

Summary of Contents for Fury 6

Page 2: ...www evolutionfury com 2 03 GB...

Page 29: ...www evolutionfury com 29...

Page 30: ...www evolutionfury com 30...

Page 31: ...www evolutionfury com 31...