www.evolutionfury.com

7

ADDITIONAL SAFETY INSTRUCTIONS

FOR YOUR TABLE MITRE SAW

WARNING:

Be sure to read and

understand all instructions. Failure to

follow all instructions listed below may

result in electric shock, fire and/or serious

personal injury.

1. Know your power tool. Read operator’s

manual carefully.

Learn the applications and

limitations, as well as the specific potential

hazards related to this tool.

2. Always wear safety glasses or eye

shields when using this mitre saw.

Everyday eyeglasses have only impact-

resistant lenses; they are not safety glasses.

3. Always protect your lungs.

Wear a face

mask or dust mask if the operation is dusty.

4. Always protect your hearing.

Wear

hearing protection during extended periods

of operation.

5. Inspect the machines power cord regularly

and if damaged have it repaired or replaced.

Always be aware of the cords location.

6. Always check for damaged parts.

Before further use of the tool, a guard

or other part that is damaged should be

carefully checked to determine if it will

operate properly and perform its intended

function. Check for misalignment or binding

of moving parts, breakage of parts, and

any other condition that may affect the

tool’s operation. A guard or other part that

is damaged should be properly repaired or

replaced at a qualified service centre. Keep

guards in place and in working order.

7. Do not abuse the cord. Never use the

cord to carry the tool or pull the plug

from the outlet. Keep cord away from

heat, oil, sharp edges or moving parts.

Replace damaged cords immediately.

Damaged cords increase the risk of electric

shock.

8. Always make sure that your extension

cord is in good condition.

When using an

extension cord be sure to use one that is

heavy enough to carry the current that your

tool will draw. An undersized cord will cause

a drop in line voltage, resulting in loss of

power and overheating.

9. Do not use the tool while tired or under

the influence of drugs, alcohol or any

medication.

Following this rule will reduce

the risk of electric shock, fire or serious

personal injury.

10. Save these instructions. Refer to

them frequently and use them to instruct

others who may use this tool.

If someone

borrows this tool, make sure they have

these instructions also.

11. When the correct blade to cut the

material has been fitted, this saw is

recommended for cutting steel and

ferrous metals, aluminium and non-

ferrous metals, wood, and plastic only.

12. Do not use saw blades with High

Speed Steel (HSS) or blades that are

damaged or deformed.

13. Replace the table insert when worn.

14. Use only saw blades recommended

by the manufacturer and which are the

exact bore and diameter required for this

machine.

15. Connect your mitre saw to a dust

collecting device (O.D.Ø32mm) when

sawing material likely to cause dust.

16. Select saw blades in relation to the

material to be cut.

Use only genuine

Evolution or Evolution recommended

accessories.

17. Check the maximum depth of cut.

18. When sawing long work pieces,

always use extra support to provide

better support, and use clamps or other

clamping devices.

19. Make sure the operator is adequately

trained in the use, adjustment and

operation of the machine.

20. Provide for adequate room lighting at

your workplace or for adequate lighting

of the immediate work area.

21. Refrain from removing any cut-offs

or other parts of the workpiece from

the cutting area whilst the machine is

running and the saw head is not in the

rest position.

Never reach around the saw

blade. Turn off tool and wait for saw blade to

stop before moving workpiece or changing

settings.

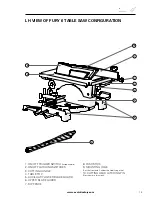

Summary of Contents for Fury 6

Page 2: ...www evolutionfury com 2 03 GB...

Page 29: ...www evolutionfury com 29...

Page 30: ...www evolutionfury com 30...

Page 31: ...www evolutionfury com 31...