www.evolutionfury.com

14

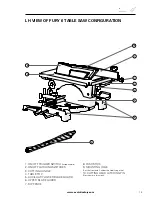

GETTING STARTED

WARNING:

ALWAYS DISCONNECT

THE SAW FROM THE POWER SOURCE

BEFORE MAKING ANY ADJUSTMENTS.

Refer to the “Service Parts Diagram”. Install

a blade as detailed in the “Installing or

Removing the Blade” section.

NOTE:

We recommend that the operator

reads the

‘Important Information’

sticker

applied to the table of the Fury6. Practicing

and becoming familiar with the procedures

outlined on this sticker will make subsequent

adjustments/assembly or configuring fairly

straightforward.

PERMANENTLY MOUNTING THE FURY6

TABLE/MITRE SAW (Fig. 1)

WARNING:

To reduce the risk of injury from

unexpected saw movement, place the saw

in the desired location either on a workbench

or other recommended leg set. The base of

the saw has four holes to mount the mitre

saw. If the saw is to be used in one location,

permanently fasten it to the workbench or

leg set using appropriate bolts with lock

washers and nuts.

NOTE:

When permanently mounting the

Fury6 we recommend that the four (4)

rubber feet located underneath each of the

mounting holes are removed and stored

safely for possible future use.

1. Tighten the mitre and bevel locks.

2. Position the saw so other people cannot

stand behind it. Thrown debris could injure

people in its path.

3. Place the saw on a firm, level surface

where there is plenty of room for handling

and properly supporting the workpiece.

4. Support the saw so that the table is level

and the saw does not rock.

5. Bolt or clamp the saw to its support.

For Portable Use (Fig. 2)

NOTE:

The Fury6 is designed to be a highly

portable machine.

For portable use the Fury6 must be fitted

with the two (2) rear Stabilising Arms.

To fit the Stabilising Arms:

•

Remove the cross head machine

screws from the two (2) rear mounting

positions.

•

Attach the Stabilising Arms with the

machine screws, two per arm and

tighten securely.

NOTE:

The Stabilising Arms are fitted with

rubber feet. The base of the Fury6 is also fitted

with four (4) identical rubber feet positioned

underneath the mounting holes in the base.

When used as a portable machine the six (6)

rubber feet provide the security and stability

necessary for safe operation.

1) Hex headed bolt M8 X 75

2) Spring washer

3) Flat washer

4) Mitre saw base

5) Workbench

6) Flat washer

7) Spring washer

8) Hex nut

9) Lock nut

Fig. 1

9

5

6

7

8

3

4

2

1

THESE ITEMS

ARE

NOT

SUPPLIED

M8 x 75

Summary of Contents for Fury 6

Page 2: ...www evolutionfury com 2 03 GB...

Page 29: ...www evolutionfury com 29...

Page 30: ...www evolutionfury com 30...

Page 31: ...www evolutionfury com 31...